Due to the COVID-19 pandemic, parent-child relationships have been emphasized, and playing gaming consoles together at home has become a popular entertainment option. Various gaming console manufacturers have been launching products one after another, leading to an explosion in sales. However, as we transition into the post-pandemic era, have you experienced your gaming console crashing, rebooting, or even shutting down for no apparent reason after 2 to 3 years of use? These issues primarily stem from the aging of electronic components inside the gaming console after several years of use, leading to decreased efficiency or poor heat dissipation, which could result in crashes, malfunctions, reboots, or even shutdowns.

Gaming Console Overheating Issues

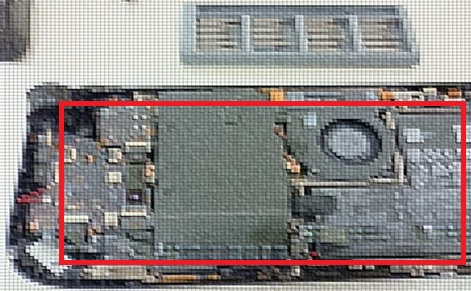

Gaming consoles comprise high-speed electronic components (CPU, GPU, memory card) and other components like screens and speakers. These components will consume a considerable amount of power during prolonged operation, which leads to the rise of the temperature of the gaming console. When the generated heat cannot effectively dissipate, the console may become heated, and in severe cases, it might overheat and crash.

For many end-users seeking high-performance 3D gaming experiences, they often set graphics to the highest quality. Some games heavily tax processors even without maxing out graphics settings. This additional strain exacerbates the burden on the console, leading to increased temperatures. This situation can be analogized to the cooling systems in computers with CPUs and GPUs, where fans help dissipate heat generated during high-speed computations. However, gaming consoles lack fans, relying solely on passive cooling through the chassis. Under prolonged high-performance usage, the back of the console may become warmer or overheated, which could lead to crashes, malfunctions, reboots, or shutdowns over time.

Case Sharing: High Accelerated Life Testing (HALT)

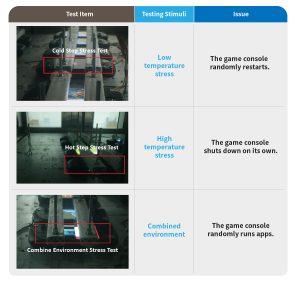

Allion collaborates with numerous gaming console manufacturers. Through rich experience in practical testing, we encountered issues during the first phase of HALT, such as consoles experiencing reboots, self-shutdowns, or opening random apps. Drawing from past testing experiences, Allion provided R&D engineers with corresponding root causes, debugging directions, and suggestions for design modifications or component replacements, thereby enhancing the console’s tolerance to environmental stress and reliability.

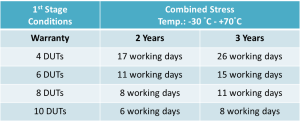

After completing the first-phase HALT testing and further debugging and verification by engineers, limits of high/low temperatures and vibrations were identified. Then, engineers calculated the accelerated aging factors caused by external stress conditions to perform the second-phase HALT testing. HALT is a reliable testing aiming to verify whether a product can achieve the warranty period under complex stress conditions, ensuring users can use the product normally within the warranty period.

The theoretical basis of this verification method lies in the Arrhenius Equation and Eyring Equation. Allion utilizes the relationship between rate constants and temperature as well as absolute reaction rate theory to calculate the acceleration factors. Additionally, the Student’s t-distribution is used to increase confidence levels. This method has been successfully implemented in collaboration with international manufacturers to verify various 3C products.

For example, conducting the HALT testing with ten consoles under the following conditions in the second phase only requires 8 working days. When all tests are done without issues, it ensures a 90% confidence level that the product will meet the 3-year warranty.

- Temperature: ±10 ℃ and Vibration 80%

- Temperature setup: -20 ℃~+60℃

- Vibration setup: 8~40Grms

- Temperature rise time:5minutes

- Burn-in time:20minutes

Faster, Easier, Better! High Accelerated Life Testing (HALT) Service

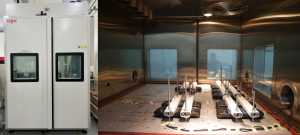

Allion is the only laboratory in Asia capable of conducting Typhoon 8.0 High Accelerated Life Testing, enabling customers to identify product weaknesses and improve designs quickly.

Faster

- The first-phase HALT testing can be completed in 5 to 10 working days. In the second phase, multiple consoles can be prepared. For instance, verifying a 3-year warranty with 10 consoles only takes 8 working days. This offers customers a better choice within a limited time and cost than traditional reliability testing, which may take several months or even longer.

- When customers cannot present during testing, Allion provides daily status reports, allowing companies to track the progress and issues encountered each day.

Easier

- Companies can remotely control or observe the status of DUTs through the app, making it more convenient to enhance product quality and overall performance.

- If issues arise during testing, companies can provide SOPs for replacing components or PCBA. Then, Allion can promptly help replace the required parts and continue testing.

Better

- With a professional technical team and extensive experience, Allion can identify design flaws during the first-phase HALT testing and determine temperature and vibration limits, assisting R&D engineers in improving the console’s reliability. Subsequently, based on the extreme values, the second-phase HALT is designed, where the laboratory can provide testing services tailored to the product’s requirements for the warranty period.

If you have any needs or questions, feel free to contact Allion!

More from Allion