What Is a Lithium Battery?

The lithium-ion battery, commonly known as the lithium battery or LIB) is a type of battery that uses lithium metal or alloy as the negative electrode material and utilizes a non-aqueous electrolyte solution. Due to lithium metal’s chemical properties, lithium metal processing, storage, and use have very high environmental requirements. Lithium-ion batteries have a mixture of gels and polymers. The positive or negative electrode of the battery must have a sponge-like physical structure to receive or release lithium ions. Lithium ions move out of the negative electrode material into the electrolyte when charging. Like water entering a sponge, lithium ions will be embedded in the pores of the positive electrode material. The discharge process is the opposite.

The lithium battery often used in the 3C industry is a lithium-cobalt battery. Generally, a rechargeable lithium battery refers to a graphite negative electrode, or a positive electrode using cobalt, manganese, or iron phosphate. It also has an electrolyte that transports lithium ions. Lithium-ion batteries have successfully developed and commercialized lithium-ion secondary batteries (LIBs), which can be used repeatedly after charging. This is because the compounds used in the positive and negative electrodes of LIBs allow the entry and exit of lithium ions. Lithium ions can travel between the positive and negative electrodes during charging and discharging without irreversible structural changes.

The standard terminal voltage of a lithium battery is 3.7 V, but it can reach 4.2 V when fully charged. Due to high energy density, no memory effect, and long cycle life, many 3C products now use lithium-ion batteries as power sources. Lithium batteries are susceptible to over-discharging and over-charging. In addition to shortening the battery’s life if used incorrectly, there may even be safety concerns about thermal runaway leading to explosion and combustion. Lithium batteries are usually equipped with protection circuits, or the battery cell structure is designed with an explosion-proof mechanism.

Lithium-ion batteries work by moving ions between the positive and negative electrodes. Theoretically, this mechanism should work forever, but cycling, heat, and aging can degrade performance over time. That’s why manufacturers specify Li-ion batteries’ life at 300 to 500 discharge/charge cycles.

Since lithium-ion batteries are stressed when exposed to heat, it is also critical to charge the battery at an appropriate charge voltage. A battery temperature above 30°C (86°F) is considered high temperature, and for most lithium-ion batteries, a voltage above 4.10V/cell is considered high voltage. Exposing the battery to high temperatures and leaving it in a fully charged state for an extended period is more likely to cause battery failure than repeated recharging.

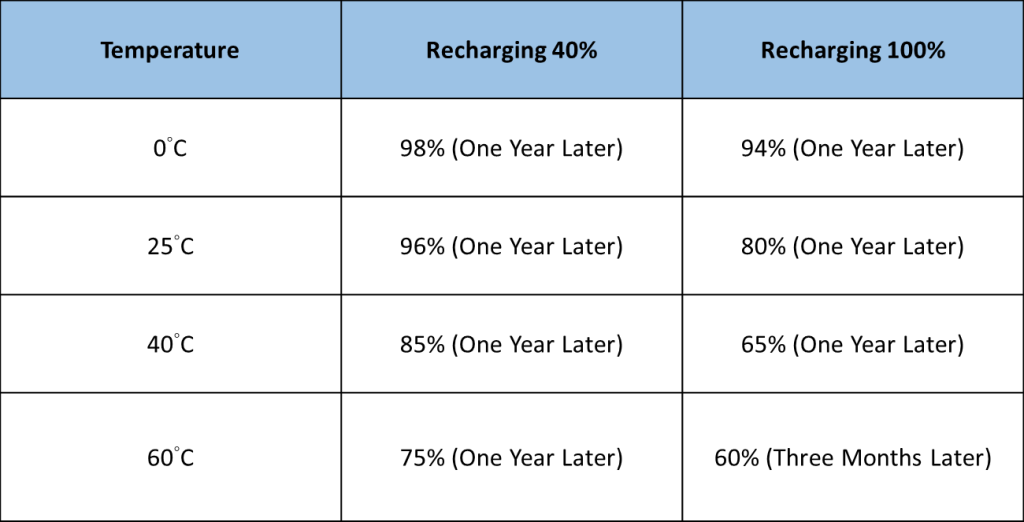

According to Battery University, if the battery is recharged to 40% at a temperature of 0°C, the battery can still maintain 98% of the original factory capacity after one year. If the battery is recharged to 100%, the battery can still maintain 94% of the original factory capacity after one year. But with the increase in charging temperature, charging at 60°C to 100% will reduce the battery capacity to only 60% of its original capacity in just three months.

Resource: Battery University

Since wireless charging relies on electromagnetic induction technology, the magnetic coil after power-on will produce a change in the magnetic field, driving electrons to flow and generate a rechargeable current resulting from the current generating heat energy. The faster the charging, the higher the heat energy generated, which means the wireless charger not only charges the battery quickly but also decreases battery health slowly. Controlling the temperature during charging has become the most important consideration for wireless chargers.

Temperature Vs. Charging Speed

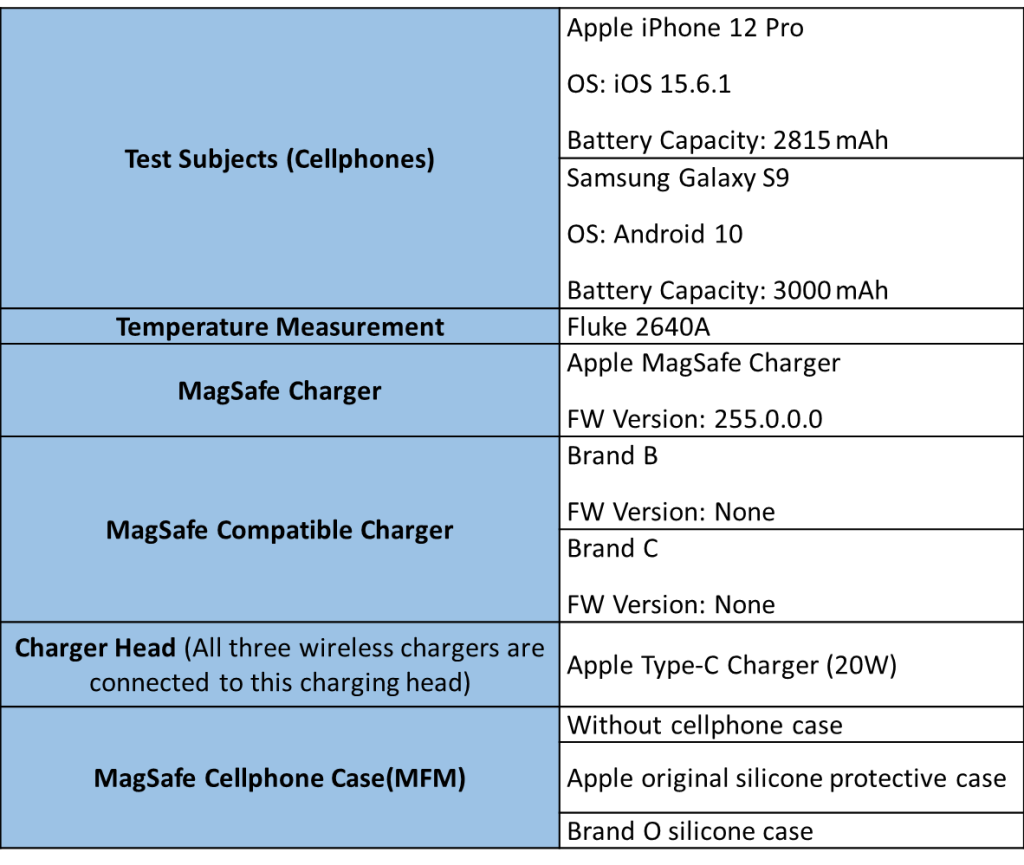

To determine whether the charging temperature is related to the charging speed, Allion uses the following equipment to conduct related experiments:

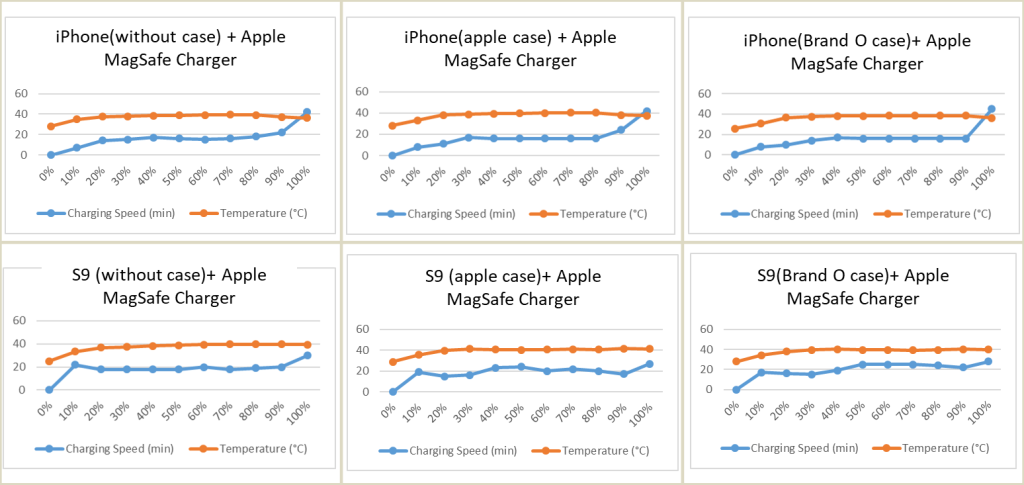

The performance of the original MagSafe charger is shown in the figure below:

When charging the iPhone with Apple’s original MagSafe charger, the charging time is the shortest when charging from 0–30%. The charging time is the longest when charging from 80–100%. Between 30% and 80%, the charging is paced evenly, taking 20 minutes to charge 10%. In terms of temperature, the average temperature is about 40°C, and the temperature drops after reaching 80%. This means that Apple is good at controlling charging speed and temperature. It does not sacrifice battery health and a charger for fast charging. On Samsung mobile phones, it may be limited by the different characteristics of Samsung mobile phones and wireless chargers. The charging time between 0% and 10% is relatively long at approximately 20 minutes. After adding the mobile phone case, the charging becomes inconsistent compared to a caseless phone, sometimes charging quickly and at other times slowly. Although similar in charging temperature—close to 40°C—Apple mobile phones perform steadier when comparing the two brands, with Apple’s official charger also fair better in terms of battery management.

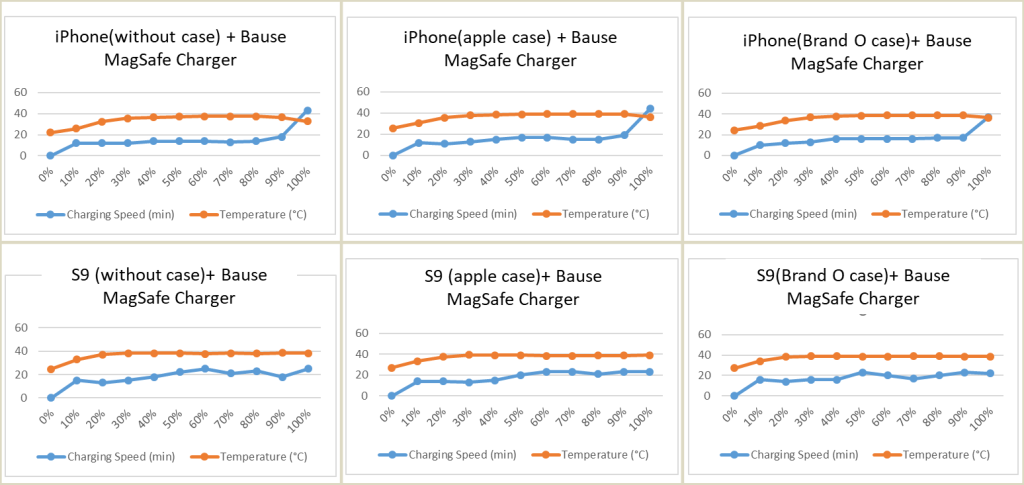

The performance of the MagSafe Compatible Charger made by Brand B is shown in the figure below:

On Apple mobile phones, the MagSafe Compatible Charger by Brand B yields a similar charging performance to that of Apple’s original MagSafe charger. But after adding the protective case, the charging of the Samsung mobile phone is steadier, taking 20 minutes to charge 10% while maintaining a temperature of around 40°C. The Apple mobile phone, on the other hand, takes slightly longer to recharge after the last 80% with a noticeable temperature drop after 80%. Since Samsung mobile phones show steady charging even after adding a protective case, the mechanism for battery protection may be weaker than that of Apple, posing a greater risk to battery health over time.

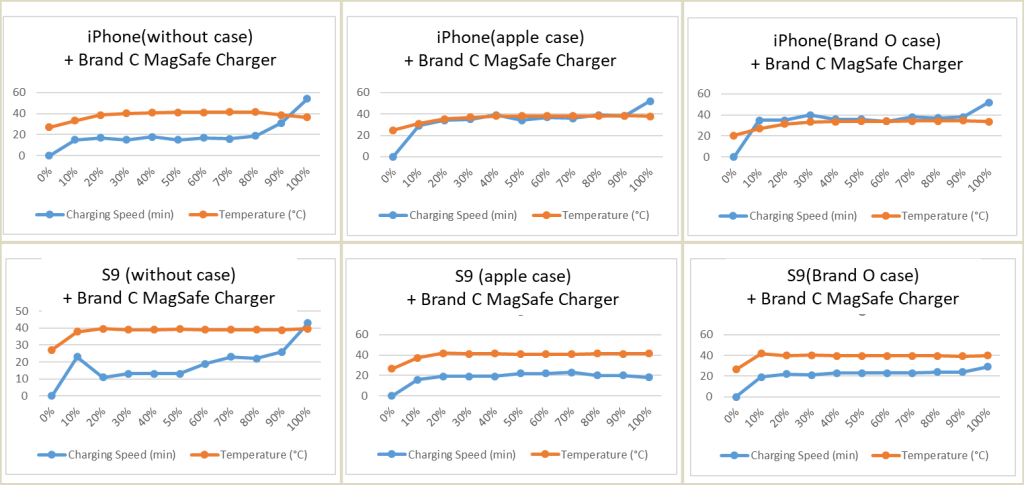

The performance of the MagSafe Compatible Charger by Brand C is shown in the chart below:

On Apple phones with protective cases, the MagSafe Compatible Charger by Brand C yields takes 40 minutes to charge 10% while maintaining a temperature of around 40°C. The charging time becomes much slower with the protective case. It may be because the protective case interferes with the electromagnetic induction between the MagSafe charger and the Apple mobile phone, so charging is very slow. It is more normal to charge a Samsung mobile phone after adding a protective case. The charger takes 20 minutes to charge 10%. When charging the bare phone, it can be seen from the battery curve that the charging time is quite irregular. Compared with Apple and Brand B, larger brands have tested and verified chargers that are more secure for mobile phones and recharge.

Temperature Measurement Service for MagSafe/MagSafe Compatible Charger

In the future, mobile phones may change from traditional cable charging to wireless charging, reducing water and dust ingress and mobile phone failures. Therefore, manufacturers will be prioritizing the development of products that support wireless charging in the future. Wireless chargers must provide fast, safe charging with reliable temperature control. For MagSafe/MagSafe Compatible/wireless chargers, Allion provides the following tests:

- Compatibility Test

- Functionality Test

- Stability Test

- User Experience Test

- Competitive Analysis and Consulting

In addition to the above-mentioned test plans, Allion can customize test plans according to different products of customers, participate in the development and design at the early stage of product design, and assist customers in producing high-quality products to boost brand reputation. We have the most complete and comprehensive types of equipment, including systems, mobile phones, USB hubs, power delivery adapters, and many more. With the most complete equipment and brand coverage, we are confident that we can help you maximize the potential of your products.

If you have any requirements or questions, please contact Allion.