Wearing headphones offers a quick escape from the world! Before the rise of wireless headphones, wired ones dominated the market with clear price ranges and a wide variety of types., leading to a trend of personalization. Although wireless Bluetooth headphones are becoming increasingly popular, wired headphones still maintain a certain market demand.

Following the trend of smartphones, the connection ports of wired headphones are gradually standardizing to the Type-C specification. Manufacturers must not only enhance the functionality of their products but also consider durability and reliability to ensure consumer satisfaction. There is a risk of pulling connected cables during the use of wired headphones, leading to situations such as core breakage or connector damage. Moreover, since the core is covered by an outer sheath, detecting the breakage part may be challenging, making such risks a hidden threat in the world of wired headphones.

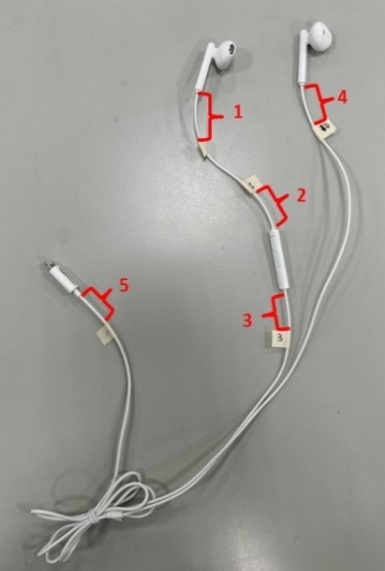

The image shows damage to the outer covering and core breakage of the headphone cable control area after being pulled. It can be seen that excessive pulling can easily damage the connection between the cable and the device, making the core more likely to break at this point.

Scenario Case

Many participants use headphones with built-in microphones during the remote conference meetings. However, unintentional pulling often occurs, resulting in issues like no sound from the headphones or microphone dysfunction. At this point, consumers may twist or entangle the cable to restore functionality. Although such actions may temporarily resolve the problem, it is possible that the core has already broken during the pulling incident. If the broken part is not properly reconnected, the malfunction will persist.

Real Case

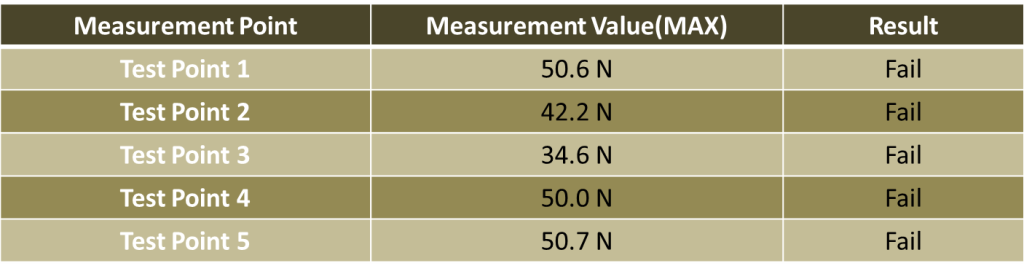

Allion has extensive experience in headphone product verification services. We have encountered wired headphones from customers for testing to confirm the fixed pull force and maintain it for a specific period. Subsequently, we assess the functionality and extended length of the headphones. Upon testing, we found that this headphone model could not meet the quality expected by the customer. If such a product were to be launched on the market, it would face the potential risks mentioned earlier.

Test Content

Conduct a pull force test at the designated five test points.

Test Conditions

Maintain for 1min when the pull force reaches 50N. The allowed extended length of the outer covering is 0.1cm, with a clamping distance of 2.54cm. After each pull test, perform a functional test on the sample.

1. Pull Force Test

Note: None of the five test points were able to maintain the pull force for 1 minute when it reached 50N. Additionally, during testing at Test Point 3, the audio function failed. As a result, the product has been deemed a failure.

2. Pull Force Test Data Chart

Test Point 5

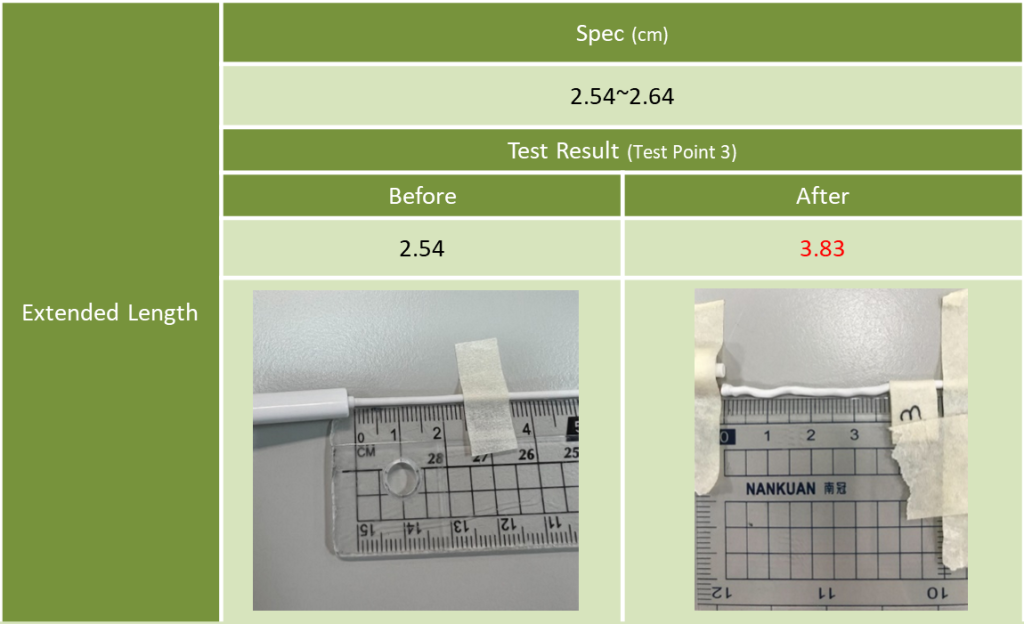

3. Outer Covering Extended Length

Note: After conducting the pull force test at Test Point 3, it was observed that the outer covering was excessively extended, causing the internal wire core to break. This led to the failure of the headphone audio function.

Faster, Easier, Better: Allion Cable Consultation Service

Allion has accumulated rich project experience, complete testing equipment and environment, offering the following advantages to meet the various customer needs:

Faster:

Allion provides comprehensive verification experiments, conducts pull tests on cables according to the EIA364-38B standard specifications, and offers professional engineering consulting with efficient solutions. This enables customers to swiftly address product issues.

Easier:

Allion utilizes a dedicated pull force testing machine to mitigate potential problems. Through the integration of this machine with software, it can easily verify the cable’s tensile and elongation capabilities. Additionally, with the assistance of an instant breaking device, Allion accurately determines whether the cable meets instant breaking conditions.

Pull Force Test Machine Specifications

Model: SE-WS1220S

Test load: 5, 50, 200 (kgf)

Load accuracy: 0.2% fs

Load unit: optional g, kg, N, lb

Maximum test stroke: 150mm

Test speed range: 0.1mm/min~300mm/min

Better:

With over 30 years of rich verification consulting experience, Allion can not only conduct conventional standard tests but also customize tests according to customer’s ideal special specifications. In addition, it also provides professional fixture design to improve overall testing.

If you have any requirements, please contact with us.