Connectors on electronic products play an extremely important role, as they are responsible for connecting circuits and transmitting signals throughout the device, making them an indispensable part of the internal structure. The performance and quality of these connectors directly affect the overall operational efficiency of the system, making the selection of these components critical during the design and manufacturing processes.

Among the various components of connectors, contact components are the core parts, acting as bridges within the system to ensure smooth electrical current transmission and stable signal delivery. The design and manufacturing of these contact components must take into account various environmental factors such as temperature changes, humidity, vibration, etc., to ensure their stable performance under various conditions.

When electronic products are subjected to vibration, contact components may face the following impacts and potential risks:

1. Poor electrical connections:

Vibration may cause poor electrical connections between contact components and sockets, leading to connection interruptions, signal loss, or decreased performance of electronic products. Therefore, it is crucial for applications that demand high stability and reliability, such as military, medical, and aerospace fields.

2. Wear and fatigue:

Frequent vibration may lead to wear and fatigue of contact components, especially during plugging and unplugging, which may shorten the lifespan of connectors and eventually result in equipment failure.

3. Mechanical stress:

Contact components are usually closely connected to other components on the circuit board. When electronic products experience impact or vibration, contact components may undergo mechanical stress, leading to breakage or deformation.

4. Conductivity issues:

Vibration may cause oxidation or contamination on contact components, thereby reducing the conductivity of connections, increasing resistance, and ultimately decreasing signal quality.

When the above potential risks occur, it may lead to product failures or damage, requiring users to go through the process of repair. During this repair process, users may not only face financial losses but also inconvenience in their daily lives, as well as negative experiences with the quality and brand of the product.

Such adverse experiences not only cause many troubles for users personally but also directly affect the reputation of the product brand. In addition to an increased lack of trust in the brand among consumers, poor-quality or frequently faulty products often lead consumers to adopt a cautious attitude in the market.

Practical Case Sharing

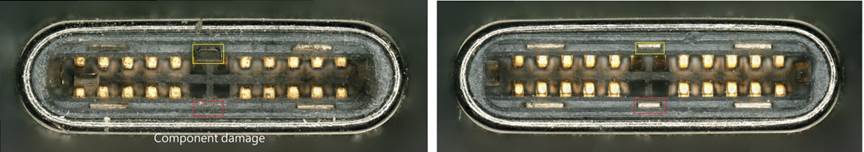

Allion has encountered cases of contact component breakdown during projects related to vibration. In a project where DUT was subjected to 0~55Grms random vibration stress continuously after being powered on, the traces of breakdown were observed on the contact components of the power module when the vibration operation limit of DUT was reached. This breakdown can generally be attributed to:

1. Possible defects in the contact components during soldering, leading to insufficient solder joint strength.

2. Possible burrs or other impurities in the contact components during soldering, causing concentrated current and local overheating.

3. Possible impact or distortion on the contact components during vibration, leading to solder joint fracture or loosening.

Allion Provides the Most Professional Solutions for Different Specifications

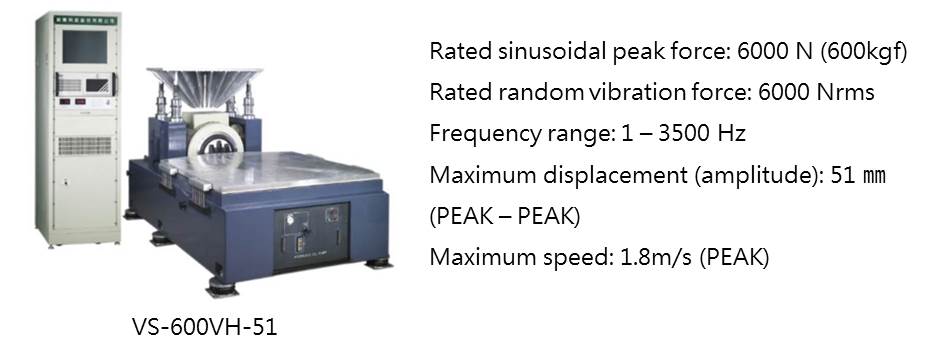

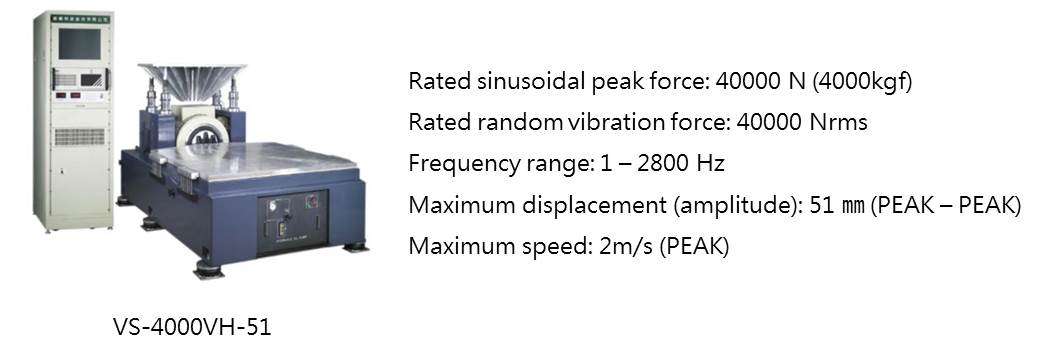

Allion has vibration test machines of different specifications, capable of testing projects of different sizes, from connector components to large-sized servers.

In addition, Allion has the following advantages:

Faster

- In addition to complete testing equipment and environments, Allion can provide customized fixture designs to meet one-stop testing services.

Easier

- Allion has professional talent to provide testing advice, and tailor the most suitable environmental tests according to product characteristics and application environments, achieving twice the result with half the effort.

- Allion also provides professional consulting on different international test standards (MIL-STD, IEC, EIA…).

Better

- Utilize high-magnification magnifying glasses to observe the causes of failure.

- Rich past testing experience provides directions for developers to modify designs or replace parts.

If you have further needs for reliability-related consulting services, please feel free to contact us through the online form.

Inquiry Form