A connector is a device that connects two different circuits. Usually, one end of the connector is called the plug (male) and the other is called a socket (female). When a plug and socket are connected, signals and electricity can be transmitted through them. Connectors are a very common type of component with various designs. For example, HDMI, Ethernet, USB, and power sockets are all common types of connectors. But how do you effectively use connectors universally? To do this, a credible source is needed to define the specifications.

Potential Issues with Plugging and Unplugging Connectors

Manufacturers design their electronic products according to the various specifications and standards of different connectors. To improve the functionality and appearance of the connectors, manufacturers will make special modifications or add mechanisms to them. If they fail to control the product quality during the production process, it could lead to difficulties during usage. For users, it’s very common to share their bad experiences online. An example of this was when a user was removing to remove a USB wireless receiver from their laptop, the receiver got stuck inside the USB port. The user could not pull the receiver out even after using more force. The user ended up damaging the laptop casing after repeated attempts (shown in the figure below).

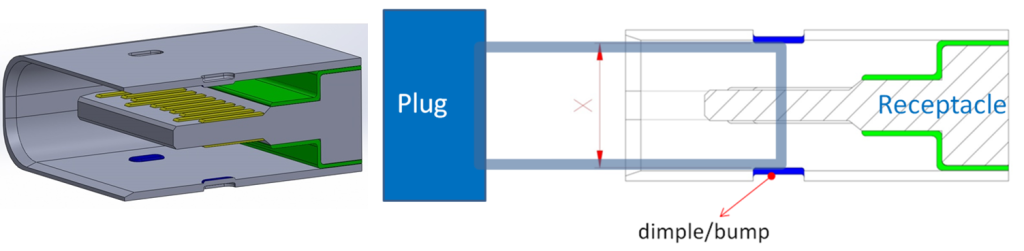

Allion’s team has also encountered various cases similar to this related to USB Type-C female connectors. To make the connectors more compatible, one of our clients altered the internal spring of their connector to a dimple design. However, during the force test, the pull force exceeded the requirements.

On the left is a 3D diagram of the female connector and on the right is a diagram of both types of connectors

During the force test, the extraction force was too large (force/displacement graph)

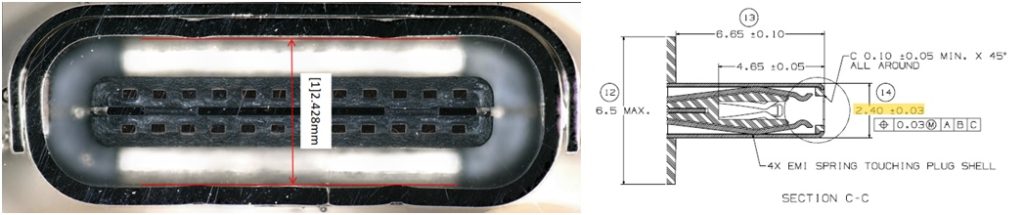

After our team discovered this issue, we used measurements to analyze it further. Finally, it was found that the height of the dimple design was not controlled well during manufacturing. This resulted in insufficient space for the male connector to enter and required excessive force to extract the connector. If this issue is not solved at this stage of the process, there will be a high risk of customer complaints in the future.

The figure on the left is a cross-section diagram of the female connector, and the figure on the right shows the maximum height of the male connector.

After products are manufactured, we can assess the quality of the products with measurements. In the example above, we could have also conducted problem analysis with measurement to find out the root of the issue. Allion owns various advanced optical microscopes that can magnify up to 200 times. With various actions like embedding, cutting, or grinding, our professional team can analyze products more in-depth and provide the correct solutions for our clients.

Faster, Easier, Better: The Most Trusted Cable & Connector Consulting Service

The figure on the left is an optical microscope, and the figure on the right is a digital microscope

Allion, a certified testing laboratory for cables and connectors, provides standard product testing, testing equipment, customized testing, comprehensive testing, and planning for various electronic products. The following includes our various services:

Faster:

Allion provides professional testing equipment for various cables and connector products. Specific testing equipment is used for different products and helps us reduce the overall testing time.

Easier:

Allion has decades of testing experience with various cables and connectors available on the market today. We can provide clients with dedicated tests or customized tests for USB, HDMI, DP, or other products.

Better:

Allion can provide professional consultation and suggestions for pre-test planning, arrangements, and post-test issues. After Allion tests your products, it is guaranteed that the design and quality will improve in the market.

If you have any requirements, please contact with us.