We live in an electronics-filled world. Electronics has become an integral part of modern life, whether it is at work, at school, or for personal use. Electronic products come in a variety of interfaces, with USB being the most common. These interfaces can be found in computer peripherals (such as mice and keyboards), data transmission cables, and USB thumb drives, all of which involve frequent plugging and unplugging. We all know how to charge our smartphones by constantly plugging in cables. However, frequent insertions and withdrawals may damage the connector and hinder connectivity. Therefore, how manufacturers select their USB connectors can have a huge impact on the product’s lifespan.

USB connector risk factors and solutions

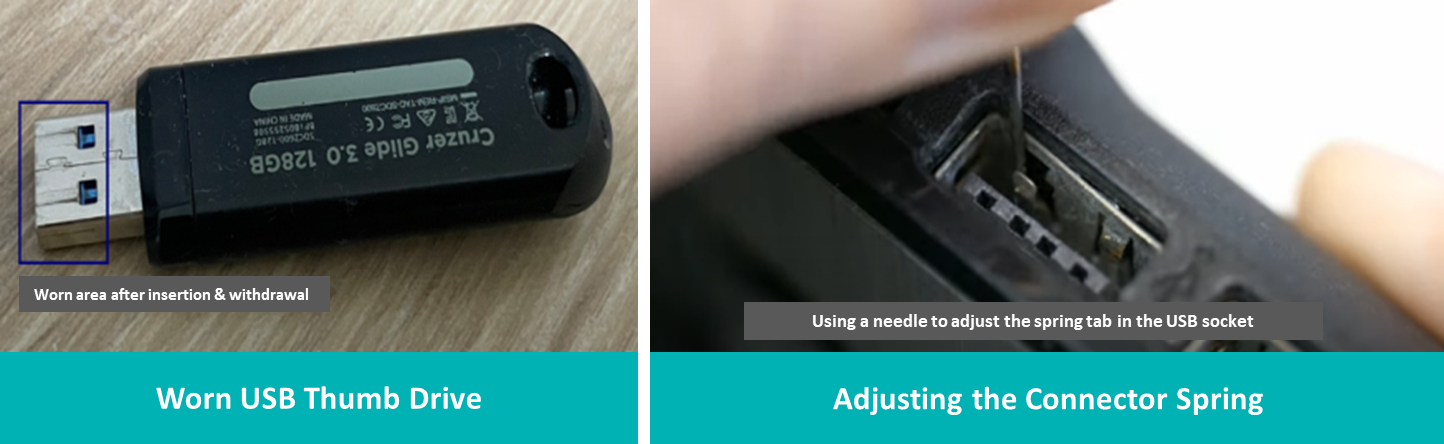

As USB has become more popular, consumers are using it more frequently and becoming more dependent on it. Heavy use, however, can also reduce the lifespan of USB connectors. We often use USB flash drives, and with every insertion and withdrawal cycle, both the thumb drive’s connector and the computer’s connector will wear. Wear and tear will eventually cause the connector to become loose and unstable, affecting the thumb drive’s connectivity with the computer.

A similar problem can be seen with the computer’s USB port. Sometimes the USB socket on a computer becomes loose after repeated insertions and withdrawals. Some users adjust the spring tab in the USB socket connector with a needle. Although this may temporarily reconnect the drive, the metal terminal (gold finger) may also be damaged, causing connection problems. In the end, it may be necessary to seek professional assistance and replace damaged connectors.

(Source: FunnyField)

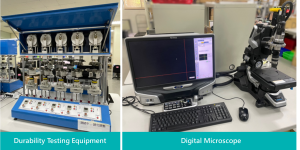

In general, consumers cannot calculate the life expectancy of connectors after extended insertions and withdrawals. Allion offers a high-quality testing environment with fully automated durability testing services, which can simulate repeated insertions and withdrawals of connectors (including sockets and plugs), thereby ensuring durability and long-term connectivity. Using the machine automation function, a large number of tests can be effectively performed to save time and money. A digital microscope can also capture high-quality images, increasing product reliability and reducing customer complaints and/or product returns.

Faster, Easier, Better: The Most Trusted Connector Testing Consultant

As a professional testing and consulting lab, Allion not only provides USB, DP, HDMI specifications, and related logo certification services, but we also conduct customized testing and assist in the development of test fixtures for various clients.

With complete integrated consulting services, Allion designs customized testing plans for connectors, assisting our clients in eliminating issues they may encounter. This ultimately enhances consumer confidence in products, protects consumer rights, and reduces the possibility of users returning their purchased products.

Faster

With our professional testing technology and rich experience, Allion can provide clients with fast and accurate certification planning that effectively shortens the certification schedule. As an official certification laboratory authorized by the USB-IF, we can also help clients quickly obtain USB certification. With industry-leading high-frequency and high-speed measuring capabilities, no matter what the product stage is, Allion is able to help our clients further accelerate the product testing cycle for various standard or special specifications.

Easier

Allion has a complete range of USB connector testing equipment and testing environments. With our testing solutions, we can ensure each client’s certification process is qualitative, quantitative, and reproducible. We can assist our clients in obtaining accurate test results easily, ensuring the quality and performance of their products.

Better

Not only does Allion have professional teams with decades of experience, but we also know how to design quantitative tests and user scenario simulations, allowing our clients to comply with requirements and user expectations. Allion’s professional teams can also provide suggestions for product modifications, assist with supplier management, and help with specifications requirements from international associations during product development. This further enhances the quality of our client’s products, ensuring high standards that comply with international specification requirements.

If you have any further needs for testing, verification, or consulting services, please feel free to explore the services online or contact us through the online form.