Introduction

Many of us have experienced charging our smartphones or electronic devices, and during this process, overheating issues with the device or phone are not uncommon. However, this heating phenomenon may arise from the battery, charging circuit IC, or another component that is often overlooked – the connector used for charging (hereinafter referred to as the Connector).

4 Potential Risks of Connector Overheating

Once the temperature of the connector exceeds a certain threshold, it may pose four major risks to electronic products:

1. Electrical Performance Degradation

In high-temperature environments, the electrical performance of the connector may be affected by increased conduction resistance and signal transmission losses. These phenomena can lead to damage or malfunction of the connector’s functions.

2. Uneven Material Expansion

Materials used in the connector may expand at high temperatures. If the expansion rates of different parts of the material are inconsistent, it can result in structural deformation or rupture of the connector, affecting its reliability and durability.

3. Poor Heat Dissipation

Connectors may generate a significant amount of heat at high temperatures. If the connector’s heat dissipation design is inadequate or the material has poor thermal conductivity, it could lead to a rapid increase in connector temperature, affecting its performance and lifespan.

4. Welding Issues

Welding points within the connector may be influenced by stress and thermal expansion at high temperatures, making them prone to breakage or loosening. This can negatively impact the connection reliability of the connector.

These potential risks not only significantly increase the likelihood of product failures or damage but also compromise the user experience. In severe cases, they may even pose a threat to consumer safety, risking lives and property.

Addressing Connector Overheating Issues

To address connector heating issues, the USB Association has developed a Connector Temperature Rise Test. This test aims to evaluate the temperature variations of the connector during the charging process. The test not only examines the performance and reliability of the connector under high-power charging conditions but also ensures its normal operation without damage or failure due to temperature rise.

With Connector Temperature Rise Test, we can assess various characteristics of the connector, such as heat resistance, temperature stability, and thermal conductivity. This helps ensure that the connector can operate stably for an extended period in high-temperature environments. Additionally, the test can be used to verify whether the connector’s design and material selection comply with relevant temperature requirements and standards.

Expert Approach

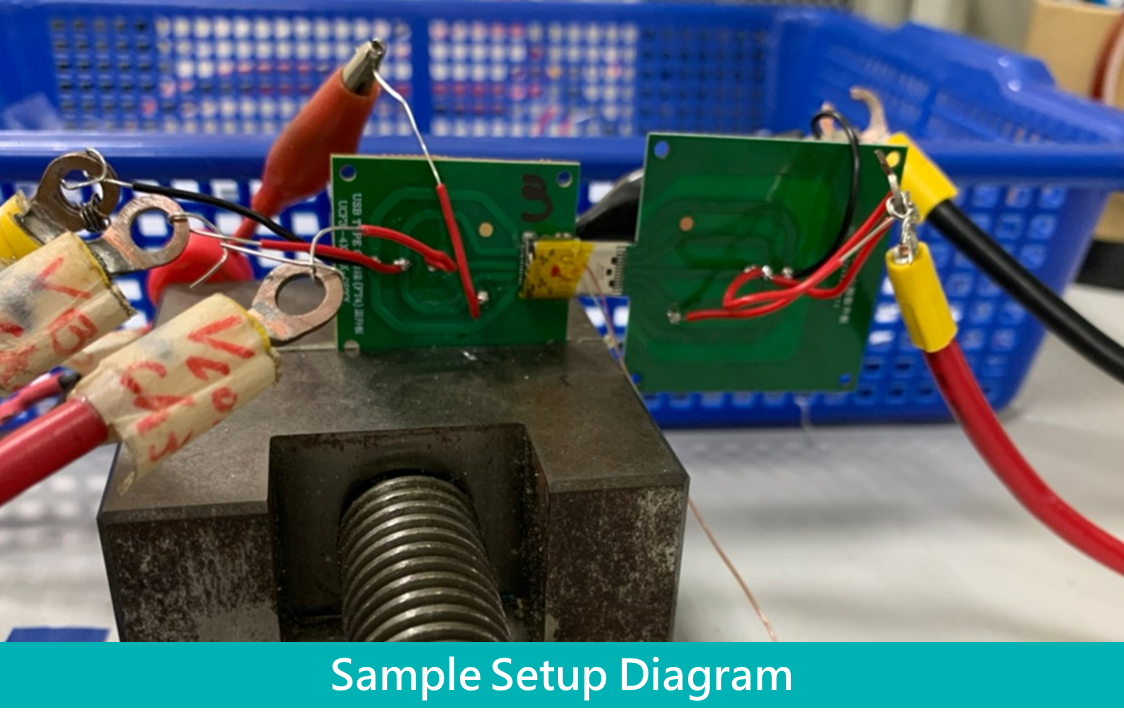

Allion utilizes Power Supply and E-Load to provide stable test currents to the connector and uses Data Acquisition (DAQ) to record the real-time temperature rise of the connector. By combining these instruments, Allion quickly simulates real-world charging scenarios, ensuring that the temperature changes during use comply with USB Association regulations.

Connector Temperature Rise Test: Real Case Analysis

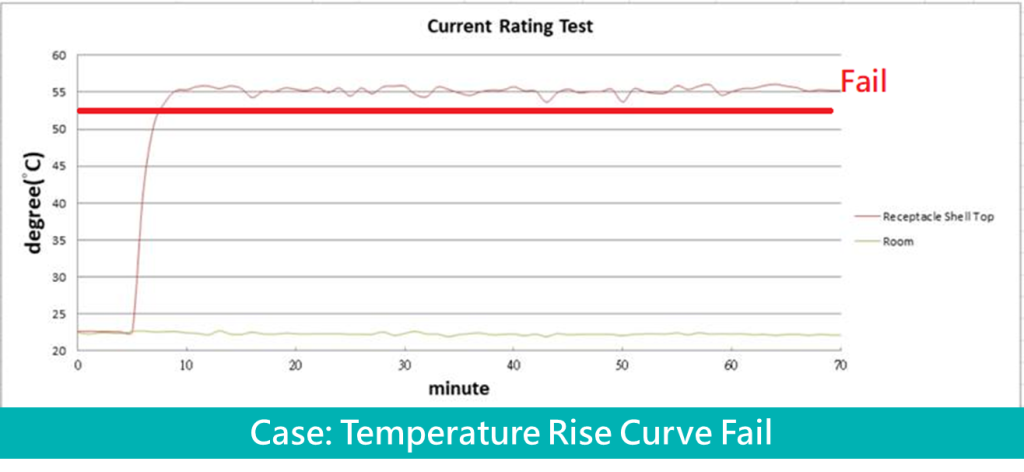

To provide further insights, we present two examples of USB certification failures:

Case 1: Impact of Connector Material on USB Certification Failure

If the LLCR value of the connector is less than 30 ohms, it can easily reach the USB Association’s specified Δ30℃ (temperature rise minus ambient temperature, typically between 23-25℃) during the temperature rise test. Higher impedance increases power consumption, promoting temperature rise.

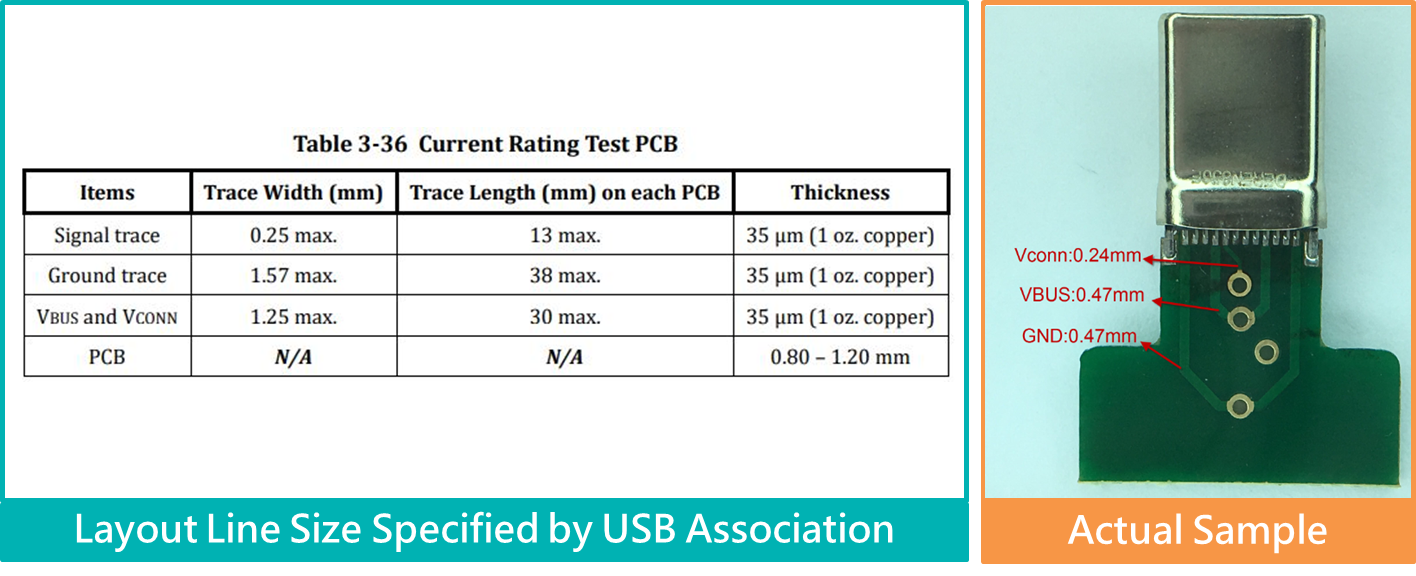

Case 2: Non-compliance of Test Board Layout Leads to USB Certification Failure

The layout lines of the test fixture should not be too thin, as excessively thin layout lines can cause temperature rise due to impedance issues.

Faster, Easier, Better! Your Validation Consultant

With industry-leading high-frequency and high-speed measurement capabilities and over 30 years of project experience, Allion, as an officially authorized USB Association certification testing laboratory, continues to provide comprehensive customized technical support for USB and cable connector-related product customers. Regardless of the product development stage, Allion can assist customers in improving product quality, optimizing production efficiency, and offering faster, easier, and better integration consulting services and solutions.

Faster

With a complete and rich testing environment, Allion assists customers in further improving product testing efficiency, ensuring quick compliance with certification requirements.

Easier

If problems are revealed during the verification process, Allion will assist customers in problem analysis and debugging support throughout, providing solution suggestions to improve potential problems in the shortest possible time.

Better

Tailoring customized testing services for various product testing needs, Allion can draw up and produce fixture boards, suggest and execute testing based on the provided testing content, ensuring adherence to relevant temperature requirements and standards.

If you have any testing, verification, or consulting service needs related to USB Connectors, please feel free to contact us through the online form

Allion Cable and Connector Validation Testing Service