What is a DAQ?

The data acquisition (DAQ) process can measure physical and electronic phenomena such as voltage, current, temperature, pressure, or sound. The data acquisition system includes sensors, signal amplification drivers, converters, and processing units. A good data acquisition design can lower costs during the work process.

An operational amplifier is a part of the signal chain of data acquisition. As the demand for sensors increases every day, appropriately amplifying signals and increasing accuracy are becoming more and more important.

Next, let’s discuss how we assist customers in developing operational amplifiers for weak voltage signals.

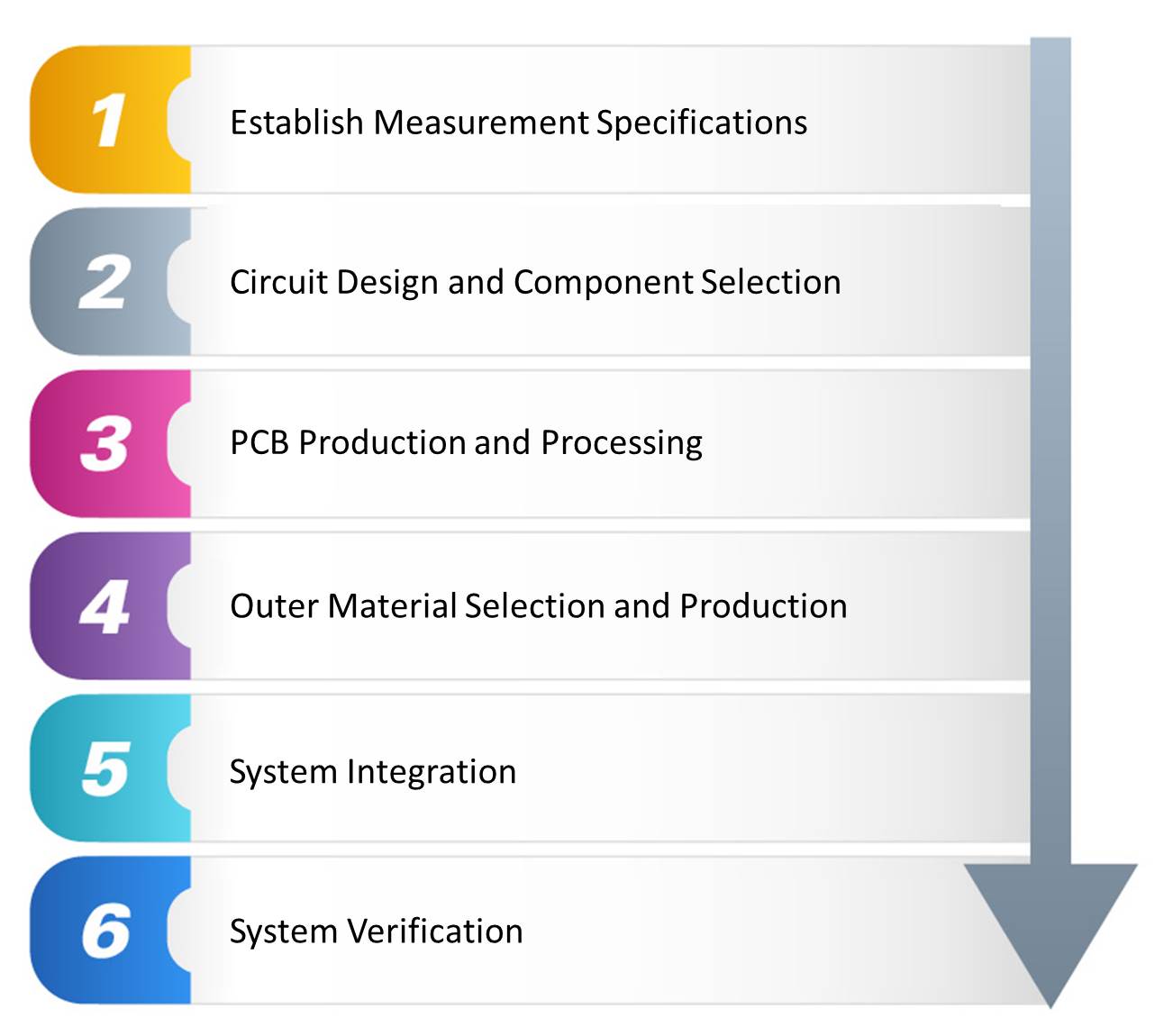

Product Design, Integration, and Testing Process

Power Supply Design Precautions

First, it’s essential to consider the range of the instrument or ADC when designing, simultaneously paying attention to the headroom of the operational amplifier. A well-designed voltage range can result in a higher resolution. In addition, it can also improve the temperature control of the operational amplifier by reducing heat.

Second, the electric power quality (refers to the ratio of AC components to DC components) should be as low as possible. Still, it is tough to eliminate AC noise from the power supply. The AC noise within the power supply will be directly reflected on the output terminal according to the PSRR of the operational amplifier. There are many ways to reduce ripples, but the best results can be obtained when targeting a specific frequency range. Finally, a sufficient current and transient response are required to minimize the distortion ratio of the amplified signal.

How to Choose the Right Operational Amplifier

When choosing an operational amplifier, you have to look at the output signal’s amplitude, form, and capability of the sensor to determine whether it is a single-ended signal or a differential signal.

The bandwidth of the amplifier is usually proportional to the quiescent current. The quiescent power consumption of the amplifier can be calculated by multiplying the supply voltage with the operating current. Selecting a high-bandwidth amplifier also means higher power consumption, so heat dissipation is also an issue to be mindful of. Solving this issue directly through PCB layout is a more favorable method.

Interestingly, maintaining the same operating temperature as much as possible often leads to higher accuracy as opposed to pursuing a lower operating temperature.

In the design stage, it’s also necessary to reduce the noise floor as much as possible through calculation and simulation to achieve a higher signal-to-noise ratio (SNR). On the other hand, stability should be considered during the design process. Whether the current should be handled by a buffer or not should be determined depending on the requirements.

Chassis Layout Precautions

Factors such as material, thickness, electromagnetic interference, and vibration can affect the output signal. Allion can assist in material selection and development.

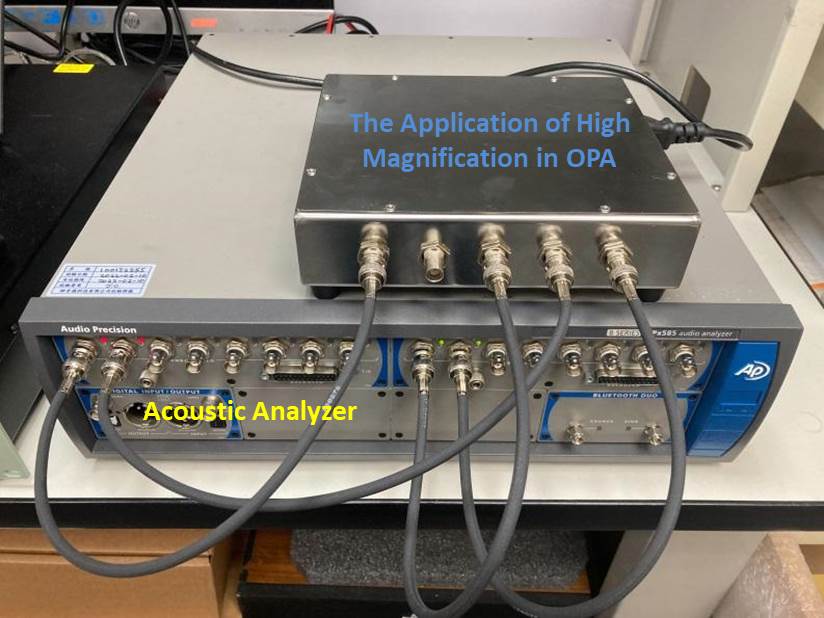

Allion Provides Various Testing Services

Allion can design all of the details mentioned above according to your requirements. In addition to testing and consulting, we also provide clients with a full range of DAQ-related design services to help you shorten the time in product development. If you’re interested in customized services and other related tests, please fill out our inquiry form and we will contact you shortly.