Outdoor security cameras have become necessary to our lives to deal with traffic management and security maintenance in modern society. If you look closely, you can see that these security cameras can be seen almost everywhere on the streets, whether you’re in a big city or a small town. Also as smart homes have become more prominent, the popularity of security cameras has been increasing alongside.

The increasing consumer demand for security cameras has prompted many manufacturers to invest in these products. Usually, each manufacturer will set requirements for product verification and testing. However, these requirements are starting to get less strict, allowing for more issues to occur with these products.

Product reliability verification is more time-consuming compared with general product quality verification. Manufacturers try to reduce reliability testing due to a lack of patience and trying to seize market opportunities. Long-term testing like high-temperature and high-humidity testing is usually overlooked. This can lead to some serious risks down the line.

What Are Tin Whiskers?

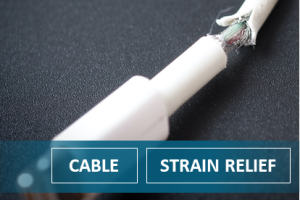

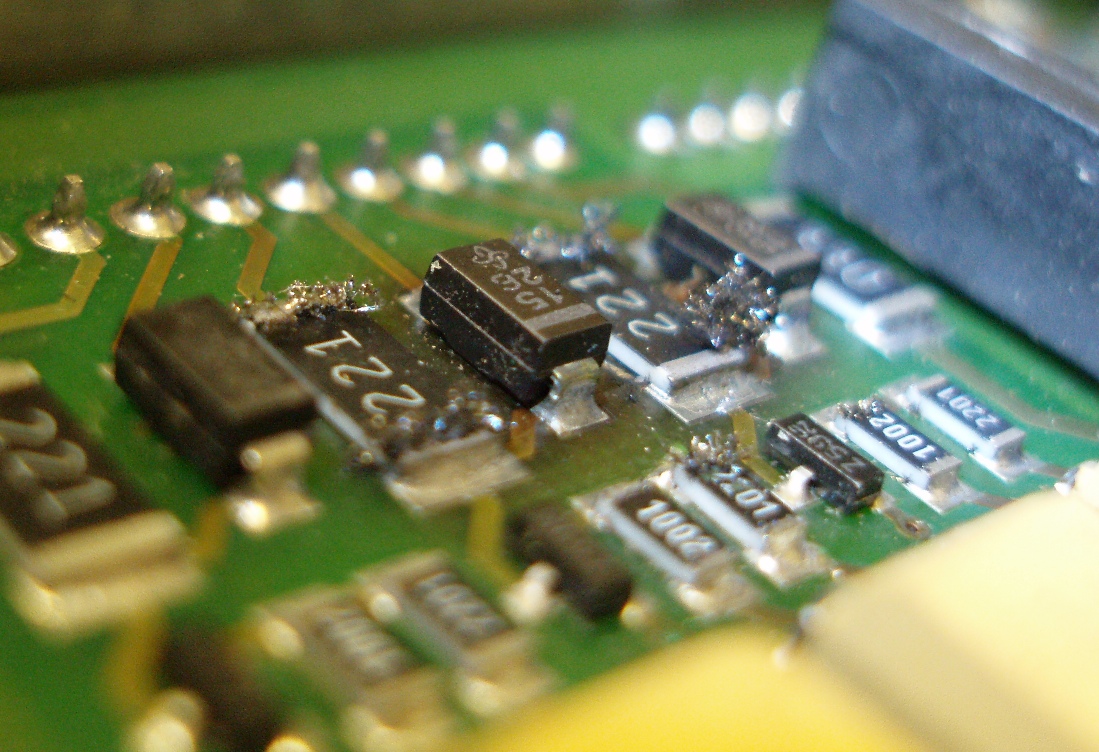

Tin whiskers or metal whiskering is a type of “stress relief”. When the surface of solder is in contact with various organic substances such as oxygen, sulfur, carbon, and others, it compresses the composition of the tin and generates internal stress. When it is relieved, the tin atoms will be expelled outwards, forming whiskers.

Recently, lead-free solder has replaced traditional solder that contains lead due to environmental issues. Lead-free solder contains over 95% of pure tin. The problem is that the more tin, the easier it is for the metal to produce whiskers. The main factors that affect the growth of tin whiskers are temperature and humidity.

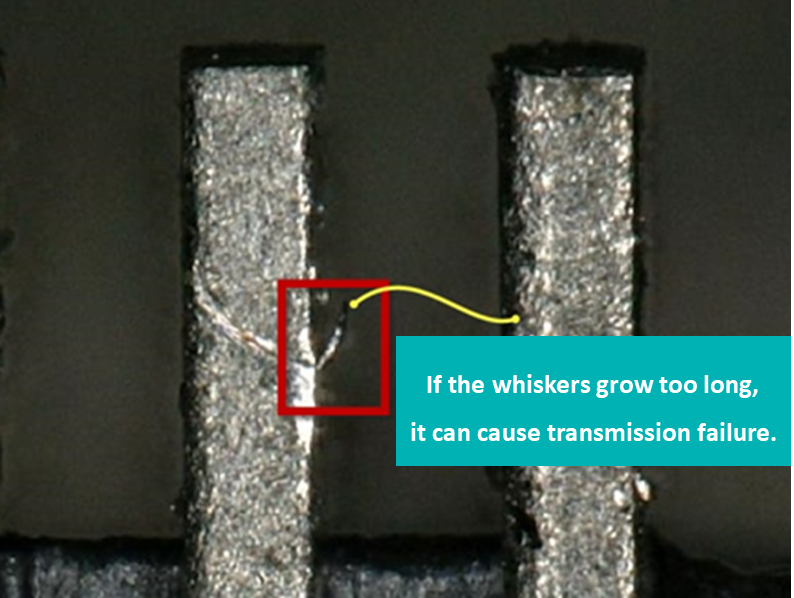

Potential Risk of Causing Failure to Electronic Products

If the whiskers grow too long and connect two pins, it can cause transmission failure, short-circuiting, or even product damage.

Faster, Easier, Better! Allion’s Product Verification Solutions

Observing Temperature and Humidity to Determine Whether There are Tin Whiskers

Allion can provide services such as various temperature and humidity testing environments. With high/low-temperature cycle testing, high-temperature testing, and high humidity testing, we can observe whether tin whiskers appear on electronic products in these environments long-term.

Professional Ability and High-quality Testing Equipment

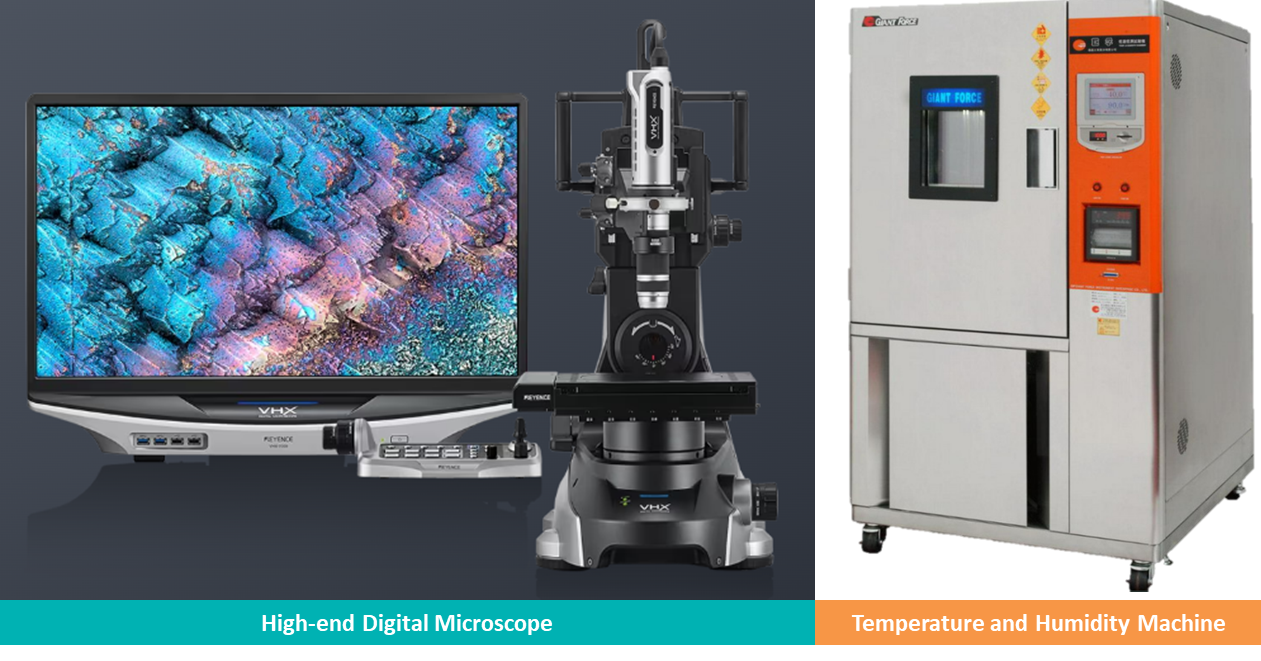

High-end Digital Microscope: This microscope has a large depth-of-field with a far observation distance that allows us to observe the surface of the tin whiskers.

Temperature and Humidity Machine: This machine provides customizable temperature and humidity environments by editing the temperature and humidity curve.

Allion is deeply rooted in the IT industry and we have accumulated over 30 years of testing and certification experience. We’ve established a large database of millions of verification data. Through comprehensive intelligent testing suggestions and analysis, Allion can bring your with a full range of automobile testing solutions, assisting them to achieve strict product quality control, and provide a faster, easier and better integrated consulting services and solutions.

Faster

Allion has a complete range of product reliability testing equipment such as various types of temperature and humidity machines, vibration machines, impact machines, and product life testing machines (HALT). Temperatures can be tested from -100°C to 200°C, and maximum vibration levels can reach 70 GRMS. Our high-frequency testing instruments and testing environments are available for clients to speed up their testing schedules.

Easier

Our decades of testing experience allow us to provide solutions and execute them in a short amount of time. If issues are discovered during product verification, Allion can also provide professional technical support services such as problem isolation, debugging support, and solution suggestions. This helps our clients obtain accurate test results more easily, ensuring product quality and overall performance.

Better

Our decades of testing experience allow us to provide solutions and execute them in a short amount of time. If issues are discovered during product verification, Allion can also provide professional technical support services such as problem isolation, debugging support, and solution suggestions. This helps our clients obtain accurate test results more easily, ensuring product quality and overall performance.

If you have any further needs for testing, verification, or consulting services, please feel free to contact us through the online form.

Contact Us