Touch Accuracy: The Key to Success for IVI Systems

In the modern automotive industry, the In-Vehicle Infotainment (IVI) system has become an indispensable part of vehicles. IVI systems improve the convenience and comfort of driving and integrate functions such as navigation, music playback, communications, and information displays. Moreover, these functions all rely on the interactive touch screen. If there is poor touch accuracy on IVI systems, drivers are likely to face operational errors and experience confusion during usage.

For example, if a driver is trying to adjust the volume and the poor touch accuracy results in switching on the music or if a driver is trying to change songs but changes the navigation destination instead, it can seriously affect the driving experience. In more serious cases, it could even put the driver’s safety at risk. Another example would be if a driver attempts to turn on the seat heating or air conditioning, but the poor touch accuracy does not allow the driver to do so, it could cause inconvenience to the driver, especially in bad weather conditions. These potential issues shine a light on the necessity of strict verification testing for IVI systems.

Entrusting a Third-party Testing Laboratory is Better for Complex Touch Accuracy Testing

When dealing with touch accuracy testing, manufacturers often encounter difficulties when simulating user behavior and improving the accuracy during repeated actions. This not only relies on high-precision testing equipment, such as the UR5 robotic arm that has an accuracy of ±0.01mm, but it is also extremely complex to calculate data and execute the test. Most manufacturers need expensive testing equipment and also specific knowledge with practical experience in testing. Therefore, manufacturers seeking assistance from professional third-party testing laboratories like Allion can efficiently allocate limited resources and time into the development of new products and features. This enhances innovation capabilities, sustaining a competitive advantage in the market.

A Closer Look of Touch Accuracy Testing

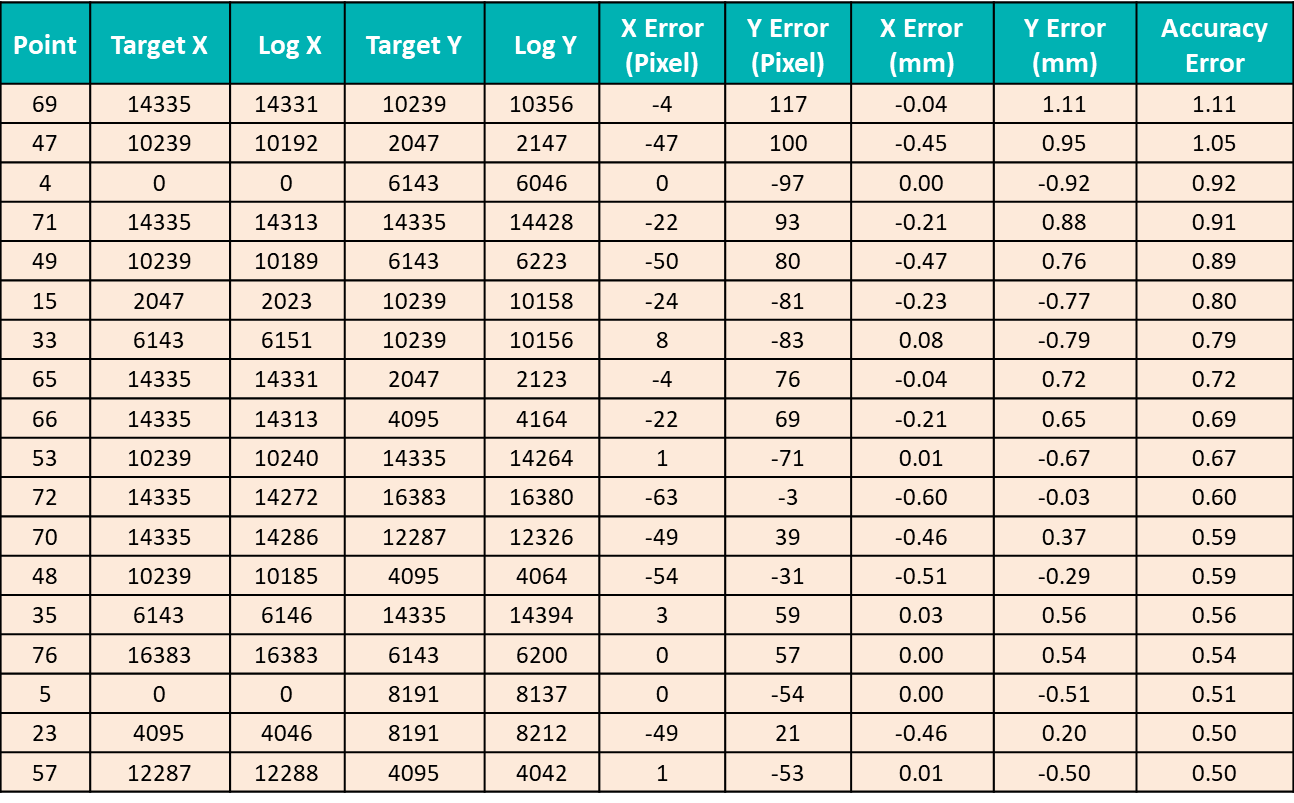

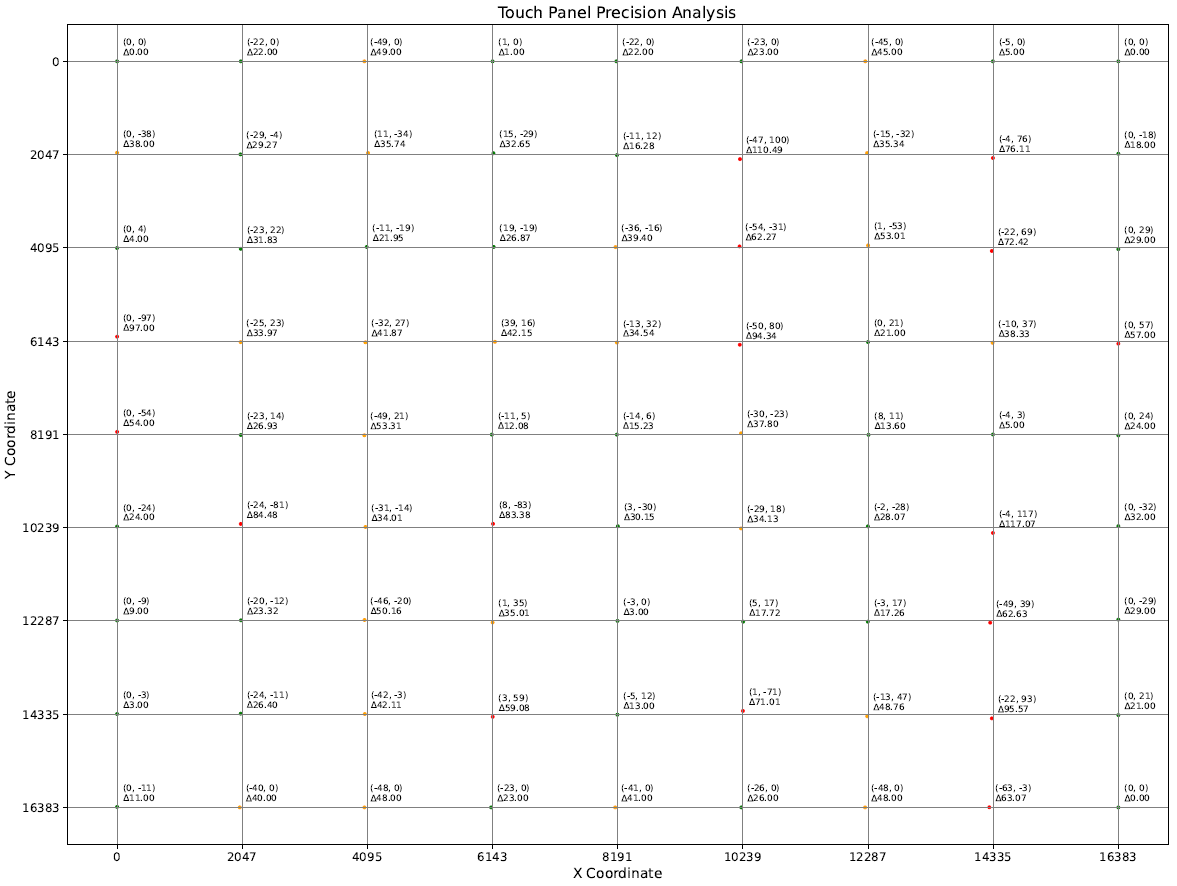

Let’s look at one of our clients, a touch panel manufacturer, as an example. They contacted Allion to verify and test the touch accuracy of their product and required the error standard to be within 1mm. By using our UR series robotic arm with a customized clamping fixture, we successfully tested 81 points. It was found that two of the points had exceeded the error standard of 1mm. Our client then made adjustments and sent the product back to us for verification once again. In the end, all of the touch points had error standards of under 1mm, meeting their requirements for shipping.

This result not only demonstrates Allion’s industry-leading technology but also reflects the urgent demand in the market for high-precision touch accuracy. Modern consumer requirements for automotive technology are constantly increasing and touch precision has become a very important factor in terms of market competition. Allion’s professional consulting team has an in-depth understanding of current market trends and can provide clients with comprehensive solutions such as technical analysis or actual testing, helping clients with their market requirements and enhancing competitiveness in their products.

Our test reports not only include a detailed data analysis report but we also provide customized solutions to help clients make appropriate changes in their products. We constantly update our testing technology and create customized solutions based on the current market trends and client needs. Allion’s goal is to help clients gain advantages in the market and increase their brand value with professional problem analysis and efficient solutions.

Faster, Easier, Better: Allion’s IVI touch panel Testing Consultant Service

Allion is deeply rooted in the IT industry and we have accumulated over 30 years of testing and certification experience. Through these professional services, Allion can bring vehicle-related clients with a full range of automobile testing solutions, assisting them to achieve strict product quality control, and provide a faster, easier and better integrated consulting services and solutions.

Faster

With our professional technology and testing equipment, clients’ verification process will be speed up and products will be able to go on the market even faster.

Easier

By implementing AI and automation solutions, Allion ensures that every test is “qualitative, quantitative, and reproducible”, helping our clients to improve product performance in a more efficient manner.

Better

Allion’s professional consulting team has rich experience with IVI testing, Bluetooth testing, and CarPlay testing. Our technical services and R&D support are also provided to ensure the performance of client’s products in various scenarios.

Allion focuses on providing clients with comprehensive services and solutions for advanced products such as IVI systems. We utilized cutting-edge technology and professional teams that are equipped with high-end testing equipment such as the UR3, UR5, and UR10 robotic arms. These arms are used with multi-axis remote controllable sliders and custom fixtures. The combination of these pieces of equipment allows us to perform extremely precise and customizable testing. Allion’s interactive simulation system can conduct evaluations and tests on response speeds, interactive performance, and user experience performance for IVI systems, accurately evaluating the performance of its touch screen under various conditions.

As a world-renowned testing and certification lab, Allion is fully committed to research and development for vehicle technologies such as CAN Bus, Automotive Ethernet, and Vehicle-to-Everything. Allion’s Customized testing solutions and global support are provided for our various clients, ensuring their products are following the latest trends in the market and contributing to the global automotive industry.

If you have any further needs for testing, verification, or consulting services, please feel free to contact us through the online form.