Electric Vehicle Cable Application Requirement: High-speed Transmission is Essential

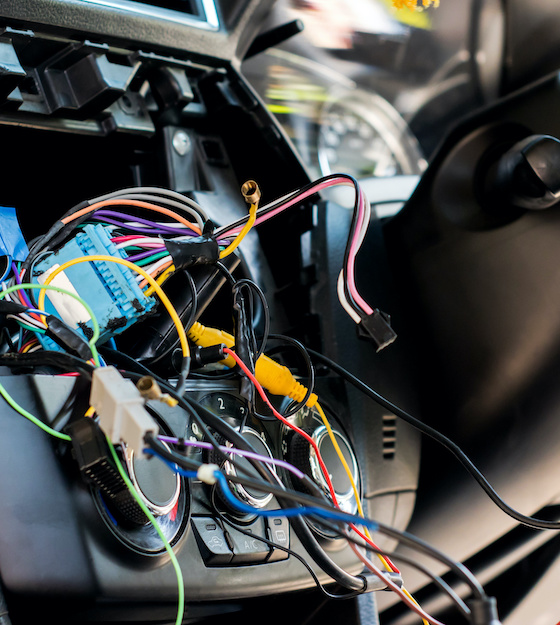

In today’s smart electric vehicles, numerous electronic components require data communication between them. High-speed cables are essential for transmitting high-bandwidth data signals, making them widely used in smart electric vehicles.

One of Allion’s major cable manufacturing clients undertook a project for a large electric vehicle manufacturer, producing USB Type-C cables for use inside the vehicles. To ensure the USB Type-C cables function properly in electric vehicles, they must meet the following requirements:

- Electromagnetic Compatibility (EMC): USB Type-C cables need to have good EMC to avoid interfering with the operation of other vehicle components.

- High Temperature Resistance: Electric vehicles have high internal temperatures, so USB Type-C cables must be capable of withstanding high temperatures.

- Vibration Resistance: Electric vehicles experience vibrations during operation, necessitating USB Type-C cables that can withstand such conditions.

However, the cables produced by the client’s cable division faced electromagnetic compatibility issues, resulting in Radio Frequency Interference (RFI) that affected the GPS functionality of their electric vehicles. As a result, they sought our services to analyze the cable issues and assist in resolving them.

Customer Challenges: Identifying Root Causes and Solutions After Discovering Issues

The cable manufacturer received feedback from their electric vehicle (EV) client regarding a GPS malfunction issue in a specific car model. Through cross-verification, they identified their supplied USB Type-C Cable as the culprit. However, despite pinpointing the source of the problem, they were unable to determine the root cause and implement a solution. The main challenges they faced were:

- Insufficient Information and Expertise: The client lacked sufficient understanding of the GPS fault information provided by the automaker and had inadequate knowledge of GPS technical specifications and design requirements, hindering their ability to make an initial judgment.

- Limited Troubleshooting Experience: The client had not encountered similar issues previously, resulting in a lack of troubleshooting experience. This left them unsure of how to approach the problem.

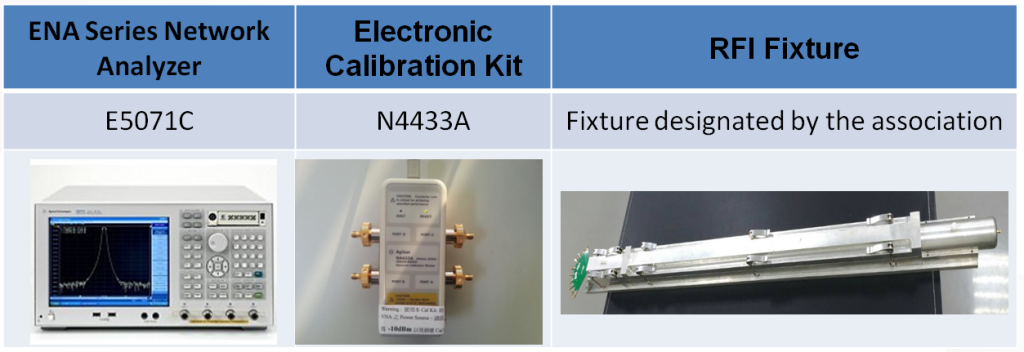

- Inadequate Testing Equipment: The client lacked comprehensive testing equipment, making it difficult to conduct thorough product testing and perform problem analysis and localization.

Solutions

In response to the customer’s issue, Allion leveraged its extensive experience and understanding of USB and GPS to provide corresponding problem analysis and debugging consultancy services.

Issue Analysis

Through experience and understanding of specifications, the Allion expert team quickly identified electromagnetic interference as the likely cause. Further analysis in the laboratory with customer samples revealed multiple holes in the design of the Type-C connector shell. These holes lacked RF interference shielding, potentially causing the abnormal functionality of the electric vehicle’s GPS.

Based on our experience, GPS typically operates in the L1/L2 frequency bands. Therefore, RFI must be able to effectively pass through these bands. The higher frequency components have minimal impact on GPS. Hence, Allion’s primary consideration is that issues may exist in the L1/L2 frequency bands, potentially leading to GPS malfunctions.

Debugging Consultancy Service

Based on our problem analysis, we have designed the following troubleshooting plan for the customer:

1. Confirm RFI Status of Original Design

Firstly, it is essential to verify whether the RFI issues identified in the customer’s original design indeed exist.

2. Treatment of Shell Holes

To address the holes in the shell, we will wrap them with copper foil to enhance the RFI shielding effectiveness.

3. Verify RFI Shielding Effectiveness

After applying the copper foil wrapping, we will re-evaluate the RFI shielding effectiveness. If it remains insufficient, further measures will be necessary.

4. Grounding of Copper Foil and Cables:

If the RFI shielding effectiveness is still inadequate, we will ground the copper foil with the cables to effectively eliminate RFI.

Through these steps, Allion has successfully assisted the customer in resolving the issue of GPS malfunctions caused by their cables.

Time to Market with Quality! Creating Value with High-Quality Services

Allion Team’s Faster! Easier! Better! Three Key Secrets

Through the professional service offerings mentioned above, Allion helps clients achieve a high-quality service experience, resolving product issues and mitigating the risk of delivery disqualification by automotive manufacturers. Our services offer the following advantages:

Faster

Allion can help clients swiftly resolve issues without the worry of being stuck without a clue. Leveraging the following strengths, we can reduce turnaround time by at least three months for clients by identifying issues early and providing timely solutions:

- Advanced Equipment: Allion is equipped with a comprehensive suite of advanced testing equipment specifically designed to address Radio Frequency Interference (RFI) issues effectively.

- Rich Experience and Expertise: With years of experience and professional analytical capabilities, we can swiftly pinpoint the root cause of problems and provide effective recommendations.

Easier

Allion’s solutions are clear and precise, accompanied by detailed guidance and assistance, ensuring smooth completion for our clients.

Better

The accumulation of experience and professional expertise enables us to develop precise and reliable troubleshooting plans. Each step is meticulously planned to ensure our clients effectively resolve their issues.

For more information on successful case studies relevant to your industry, or if you have any questions or requirements, please feel free to contact Allion at any time!