Significant Leap in Transmission Speed

Where can High-Frequency High-Speed Transmission Cables be Applied? What are the Actual Customer Needs?

In the rapidly advancing era of technology, the ubiquitous application of high-frequency, high-speed transmission cables has become indispensable. These cables are not only extensively used in high-performance systems such as automobiles and AI servers but also serve as crucial components ensuring efficient data transmission.

For instance, modern cars are equipped with a myriad of sophisticated sensors and control systems that generate vast amounts of valuable data. To ensure safety and performance, the in-vehicle cable systems must support high-speed data transmission reliably. Similarly, AI servers require high-quality transmission cables to handle big data, facilitating rapid computation and precise analysis. This capability maximizes computational resource efficiency.

High-frequency, high-speed transmission cables symbolize not only the advancement of modern technology but also guarantee system stability and performance. For manufacturers of these cables, interfaces supporting speeds exceeding 20 GHz and data volumes from multi-channel transmissions have become standard. In applications such as autonomous vehicles, any malfunction in a single channel could potentially lead to system failures, jeopardizing safety. Therefore, every cable and channel must undergo rigorous testing to ensure comprehensive system stability and reliability before deployment.

By Addressing the Problems, Promptly Comprehend the Customer’s Challenges

Allion has long assisted cable manufacturers in developing high-frequency, high-speed applications. With the continuous advancement of technology, many cable manufacturers are required by their end customers to ensure 100% testing of shipped transmission cables to guarantee product quality. Faced with these demands, numerous manufacturers have sought Allion’s assistance. However, in meeting such market requirements, customers also encounter the following four major problems and challenges.

1. Insufficient Testing Capacity

Manual testing is inadequate to meet the requirement for 100% testing capacity.

2. Customized Test Fixtures Requirement

Customized test fixtures are necessary for inspecting transmission cables, However, many clients lack the capability to develop and design these fixtures themselves.

3. Unstable Measurement Data

In addition to rapid measurements, inconsistent and inaccurate test results can confuse engineers during production regarding equipment, components, and processing issues. Manual testing struggles to maintain precision and stability.

4. Flexible Adaptation to Production Line Needs

Achieving 100% testing requires the capability to swiftly adapt to production line requirements. Unlike general-purpose instruments primarily for research and development purposes, they need solutions tailored for production line applications and more flexible software functionalities. This includes error correction, rapid sample information integration, real-time display of test data, and automated report generation—features not typically provided by conventional instrument manufacturers.

Allion’s Key Solution Enables Clients to Unlock a Surge in Productivity and Performance

In the process of manufacturing transmission cables, one of the most challenging tasks is testing for high-frequency characteristics. High-frequency testing is not only time-consuming but also requires specialized knowledge in high-frequency concepts. With the rapid development of high-frequency technology and the market trend towards 100% testing of transmission cables, customers face significant challenges.

Allion’s experts understand the difficulties associated with high-frequency measurements and extensive testing. To address these challenges, our technical consulting team has developed a comprehensive solution known as the “Allion Cable-Connector Multiport System (ACMS)”.

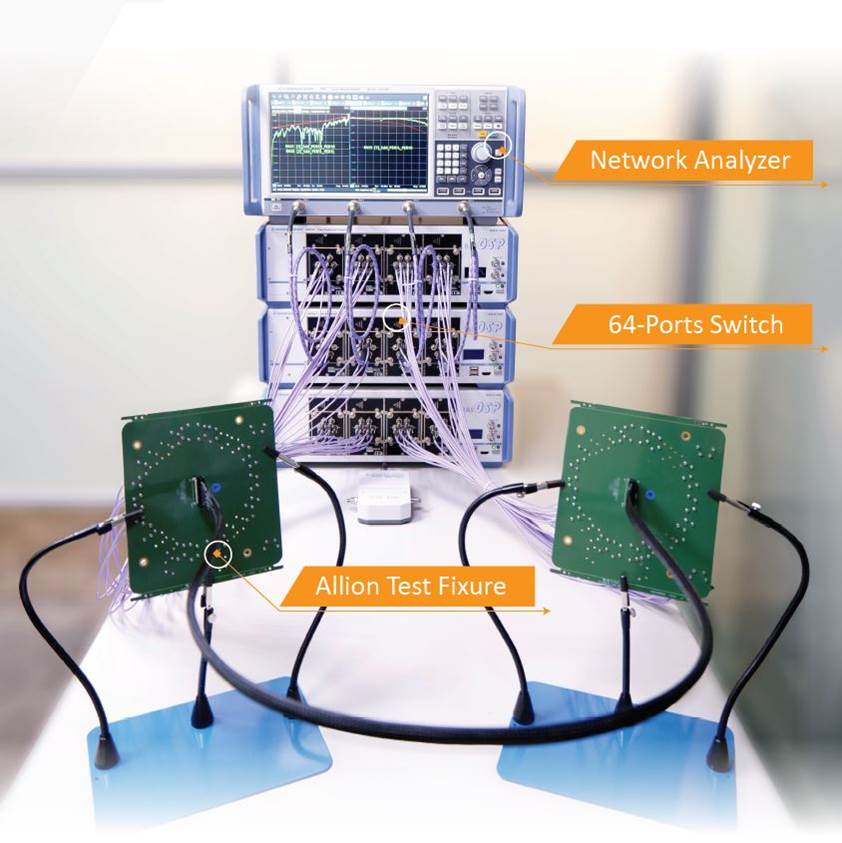

ACMS is a customizable multi-channel S-parameter automated measurement solution capable of supporting up to 67 GHz bandwidth for high-frequency testing. By connecting the ACMS series to network analyzers, 64-port switches, and test fixtures, it efficiently enables high-throughput testing and measurements, eliminating the complexities and time-consuming nature of traditional testing methods.

This solution is particularly suited for industries with high-speed transmission demands, such as enhancing server testing convenience and efficiency. It adapts to various testing scenarios and standard specifications of transmission cables and connectors. Additionally, ACMS offers customized services to meet specific testing requirements, ultimately achieving rapid, straightforward, and more efficient high-frequency automated testing, thereby advancing project timelines effectively.

Read more | Total Solution for Server with Cable & Connector

Time to Market with Quality!

ACMS Three Key Advantages Help You Overcome Challenges and Create Value!

Faster!Easier!Better!Leveraging Allion’s extensive collaboration with the cable industry and years of accumulated professional knowledge, our key solutions boast three major advantages! Assisting clients in achieving comprehensive high-frequency automated measurement capabilities and managing quality records for production lines.

Faster

Due to the competitive nature of high-frequency mass testing on production lines, where every second counts, ACMS excels in meeting customer demands by achieving production capacity and testing goals.

- Significantly Shortened Testing Time, Achieving 100% Testing:

ACMS’s exceptional performance enables manufacturers to achieve 100% product testing without sacrificing production efficiency. For example, using ACMS can complete testing of a common internal transmission cable like the MCIO Cable for AI servers in just 4.5 minutes, compared to the 8 hours required by traditional manual testing methods. This represents an efficiency improvement of over 100 times, helping manufacturers achieve 100% testing without impacting production volume and ensuring every product meets the highest quality standards. - Real-time Data Analysis to Enhance Overall Production Efficiency:

ACMS provides real-time quality data analysis, enabling manufacturers to promptly identify and address potential issues. This approach helps prevent costly downtime and ensures optimal production efficiency.

Easier

Not only does Allion’s key solution boast excellent testing speed, but it also helps customers achieve greater convenience and usability after implementation.

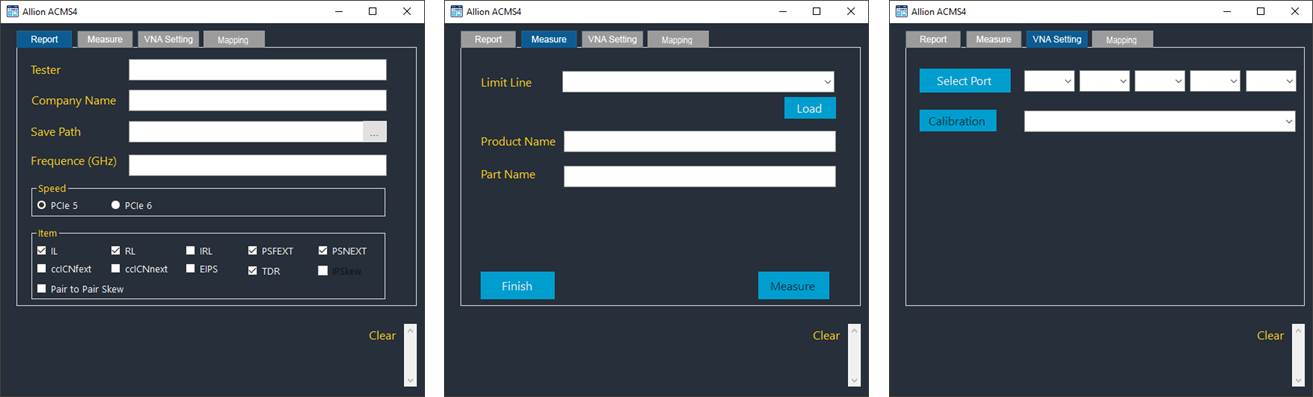

- Customizable UI Interface:

The solution offers a customizable user interface (UI) that can be tailored to meet specific cable specifications as required by the customer.

- Flexible Test Item Configuration:

Allows flexible configuration of test items and conditions based on actual needs, catering to various testing requirements.

- Support for Multiple Transmission Cable Interfaces:

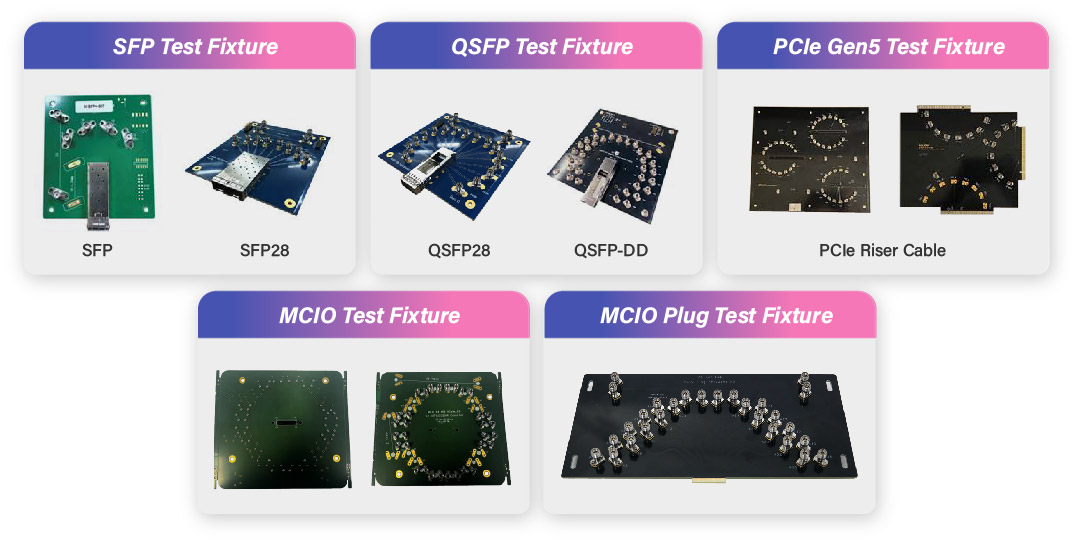

Capable of testing various transmission cable interfaces and accommodating custom requirements from customers. (Including: USB4, Thunderbolt 4/5, HDMI 2.1 UHS, DisplayPort 2.1, PCIe 5.0/6.0, SAS4, MCIO, GenZ, QSFP28/56, QSFPDD…) - Assistance with Fixture Development:

Assists customers in developing exclusive fixtures tailored for different transmission cable interfaces.

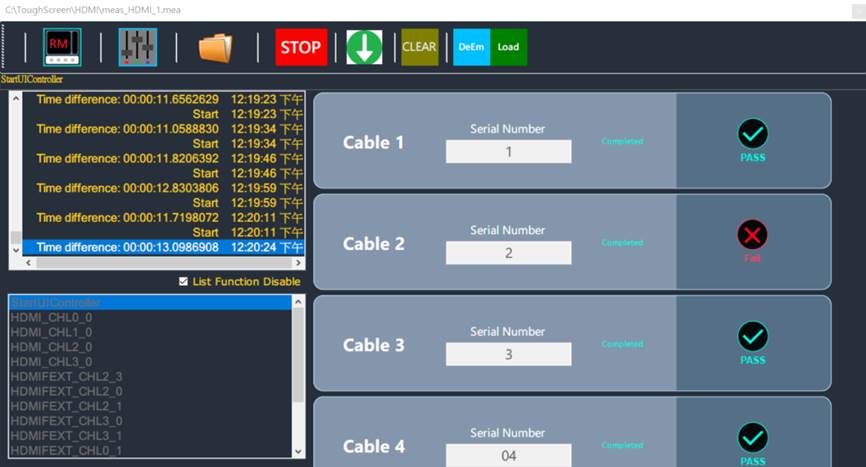

- Real-time Display of Test Results:

The data and results from the testing process are displayed in real-time, allowing testing personnel to easily monitor the latest progress of tests at any time.

- Automated Test Report Generation:

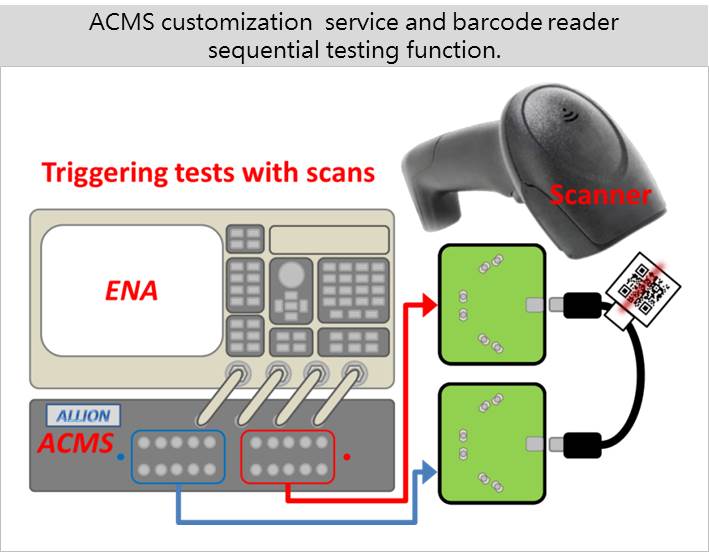

Automatically generates test reports, eliminating the hassle of manually transcribing and documenting reports after traditional manual testing. This also helps prevent errors in result recording. - Support for Barcode Scanner Triggered Test Projects:

Enables quick initiation of test projects via barcode scanners. In mass testing scenarios, this facilitates convenient data input, enhances test efficiency, and reduces time spent organizing tests.

Better

ACMS can seamlessly integrate with production line cloud-based big data systems, providing clear visibility into product data and enabling monitoring of issues such as station skips and rework occurrences during production. Through the ACMS solution, we assist customers in overcoming various challenges:

- Reducing Human Errors, Ensuring Consistency: Automated testing and report generation mitigate the risk of human errors.

- Access to Real-time Data and Product Quality History: Real-time comprehensive product data, including detailed information on each item’s production process, facilitates automated product quality history.

- Prompt Identification and Resolution of Issues: Proactively identify and address production line issues to prevent downtime and ensure optimal efficiency.

- Enhanced Time Management: Optimize production line schedules and minimize downtime.

- Improved Yield: Early identification and elimination of defects in the production process maximize yield.

- Accelerated Fault Diagnosis: Implement real-time fault detection and resolution mechanisms to minimize production interruptions.

- Reduced Production Costs: Minimize waste, rework, and downtime to optimize overall production efficiency and lower costs.

- Excellent Product Quality, Enhanced Market Competitiveness: Ensure consistent high-quality products that exceed customer expectations and deliver excellent products to the market quickly and reliably, thereby helping customers gain a competitive edge.

If you’re facing challenges with transmission cable testing and need high-quality, efficient verification solutions, Allion can help you achieve your product goals. Fill out our inquiry form now to get in touch with us.