-

Allion Server ValidationDelivering high-quality servers with consistency

Allion Server ValidationDelivering high-quality servers with consistency

Did you know that server fans

need to go through 3,000 hours of testing?

Once activated, servers must run 24/7 round the clock. Even a tiny piece of component, such as server fan, is required to deliver optimal performance in harsh environmental conditions.

Every component in the server must undergo validations to meet high performance requirements.

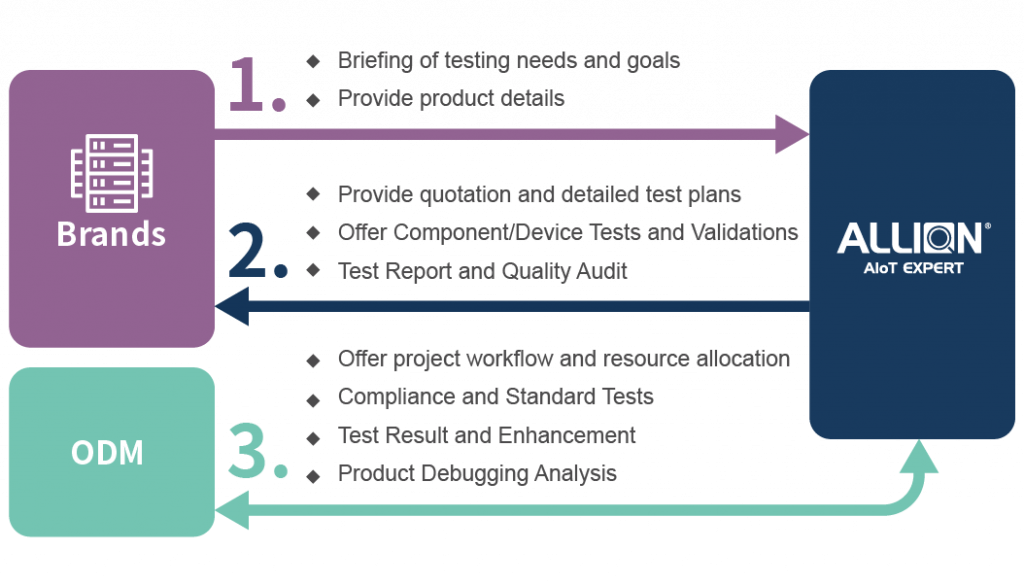

The stability of servers is rooted in the quality of the components/devices, which is how the Allion QRS Program came to be. The QRS Program assists brands in setting product specification and performance standards for ODMs to follow. This ensures that ODMs minimize failure rates by providing components/devices which achieve the set quality standards. The program also ensures that the lifespan of components/devices are within an acceptable range.

● Functionality Test

● Performance Test

● Reliability Test

● Integrated Test

● Industry Standard Test

● Performance Test

● Reliability Test

● Power Test

● Industry Standard Test

● Performance Test

● Reliability Test

● Power Test

● Electrical Test

● Mechanical Test

● Environmental Test

● Reliability Test

● Fan Performance P-Q Test

–

For more information on Allion Server Validation, please contact us.

Component validations are not enough to guarantee high-performing servers. Allion takes a step further to validate the interoperability between hardware components and system integration.

● Eye Pattern

● SSC

● Jitter Tolerance

● Bit Error Rate

–

● Power Sequence Test

● Noise Test

● DC Electronic Load Test, Performance Test, Power Margin Test

● AC Electronic Load Test

● Thermal Conductivity Test

● Environmental Test

–

–

–

● BIOS Test

● BMC Test

● OS Test

● Built-in Device Test

● Component Compatibility

● OS Compatibility

● Chip Platform Compatibility

–

● System Performance Test

● Application Performance Test for Businesses

–

For more information on Allion Server Validation, please contact us.

In a strictly tested system, any program modification can cause system errors. After a product launch, it is impossible to maintain the same level of quality control as before. Allion can help you with post-launch update testing, ensuring that your software and hardware updates can operate at the same level of stability post-launch.

For more information on Allion Server Validation, please contact us.

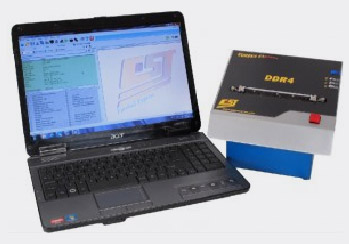

TurboCAT TCIII-3200ST

Oakgate OGT-R300-G4

CST Eureka

Hirota Smart Tester

ULINK Driver Master

Thermal Shock Chamber

Thermal Chamber

Gas Chamber

Walk-in Chamber

Model:

HALT System Model Typhoon 8

HALT System Model Typhoon 4

Features:

For more information on Allion Server Validation, please contact us.

Our goal has always been the same—providing high-quality services for our clients and partners. We offer testing services and technical support. From product road maps to the landscape of the industry ecosystem, we know what our clients need.

For more information on Allion Server Validation, please contact us.

Fill it in and talk to our most experienced experts

Leave your details and ask us anything!