Automotive Cable Application Environment

Automotive Cables: Connecting Vehicle Networks and Driving the Future of Intelligence and Safety

With the advancement of emerging technologies such as artificial intelligence, data centers, and semiconductor processes, automobiles have evolved beyond mere transportation tools to become intelligent mobile vehicles. The integration of automotive electronic systems allows drivers to reach their destinations in safer, smarter, and more personalized ways. However, the key to connecting all this intelligence and safety lies in the seemingly inconspicuous automotive cables.

Three Potential Risks Not to Be Ignored

Automotive cables are responsible for transmitting electrical signals from vehicle sensors, controllers, and actuators, acting as the nervous system of the vehicle. However, in the complex automotive environment, automotive cables face several key potential risks:

- Electromagnetic Interference (EMI): Vehicles are surrounded by various electromagnetic signals. If automotive cables lack adequate resistance to interference, it could lead to sensor misjudgments, affecting the operation of vehicle safety systems.

- Insufficient Bandwidth: As automotive electronic systems become increasingly complex, the demand for transmission bandwidth rises. If automotive cables do not provide sufficient bandwidth, it could result in signal transmission delays or losses, impacting system performance.

- Impedance Issues: The impedance of automotive cables affects signal transmission efficiency. Poor impedance design can lead to signal attenuation, reducing system effectiveness.

Automotive cables are used in diverse applications, including imaging, audio, navigation, and radar systems. In a case we encountered, a client had a cable manufacturing plant and needed to test the bare wire design of their automotive cable to ensure it met Open Alliance specifications. However, they lacked the capability to conduct these tests themselves and were unsure how to resolve the issues, so they sought assistance from Allion.

Customer’s Challenges: How to Resolve Errors under Stringent Testing Environment Requirements?

The customer wanted to confirm in advance that their product’s bare wire met Open Alliance specifications. They faced the following challenges:

Stringent Testing Environment Requirements

Automotive cable testing environments must adhere to rigorous standards to ensure the accuracy of test results. This imposes high demands on both testing equipment and fixtures. For example, testing equipment must have sufficient bandwidth and signal-to-noise ratio to accurately measure the electrical performance of automotive cables. Fixtures must ensure good contact between the test specimen and the testing equipment while avoiding additional noise interference.

To address these challenges, Allion developed a specialized Conductive Drum for automotive cable testing. This solution effectively manages the installation issues for cables with lengths of up to 10m and 15m. The Conductive Drum is made from conductive materials to ensure good contact between the test specimen and the equipment, while preventing signal interference between cables during the testing process.

Development Stage Problem Analysis

During the development stage of automotive cables, how can issues encountered during validation be identified and resolved? In this case, the customer experienced the following issue during validation. They were unable to analyze the test results and did not know where to start debugging. Allion assisted the customer by analyzing the cause of inadequate common-mode noise suppression and providing effective solutions.

- Inadequate Common-Mode Noise Suppression: Common-mode noise refers to noise conducted through the power lines that can interfere with automotive electronic systems. If the automotive cable’s common-mode noise suppression capability is insufficient, it can lead to sensor misjudgment and impact the operation of vehicle safety systems.

Solutions: How to Debug and Resolve Issues

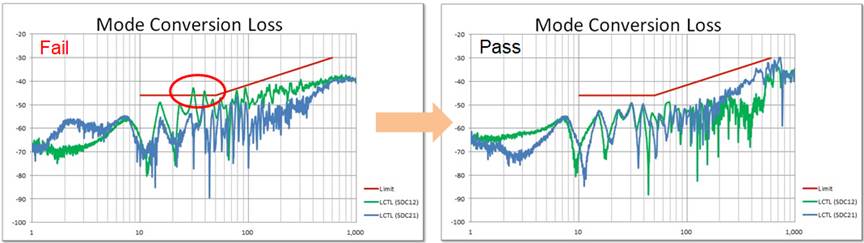

For this case, Allion has the complete validation environment and capability to assist customers in completing the required tests. We also identified a critical issue—Mode Conversion Loss failure—early on and helped resolve it.

Mode Conversion Loss Challenge with Automotive Cables

Automotive electronic equipment is often densely packed at the front of the vehicle, and with modern vehicles featuring composite transmission interfaces, excessive common-mode noise during signal transmission can potentially cause interference between devices. Therefore, Mode Conversion Loss becomes a particularly challenging issue in high-frequency control and testing for automotive specifications. Common-mode noise is invisible and intangible; despite the customer’s meticulous handling of cable grounding and shielding, the final results were still unsatisfactory.

In the case where Allion assisted the customer in validating an automotive cable, the Mode Conversion Loss of the cable, within the frequency range of 10MHz to 100MHz, exceeded the specification standards and was initially classified as a failure. After analyzing the issue and providing appropriate recommendations, Allion was able to bring the previously failing data within the standard specification limits, achieving a 7dB margin in the same frequency range.

Automotive cables not only connect electronic devices but are also crucial for the safety of drivers and passengers. Therefore, stringent quality control is essential. After discovering the issue, the customer actively sought our assistance to resolve it. Based on our extensive experience, we identified three primary causes of excessive Mode Conversion Loss:

- Poor Signal to Line Length Matching: The length and impedance characteristics of the signal transmission line must be well-matched. Poor matching can lead to signal reflection, which in turn generates common-mode noise.

- Grounding Structure Issues: The grounding structure of automotive cables must be well-designed to ensure effective grounding. Poor design of the grounding structure can increase common-mode noise.

- Insufficient Braiding Density: The shielding layer of automotive cables is made of metal braid. Higher braiding density provides better suppression of common-mode noise. If the braiding density is insufficient, it may result in increased common-mode noise.

In this case, Allion’s analysis revealed that the excessive Mode Conversion Loss was primarily due to insufficient braiding density. We recommended that the customer increase the braiding density and provided specific parameters for it. The customer followed Allion’s advice, improved the product, and successfully brought the Mode Conversion Loss within the standard specifications.

Creating Value

Time to Market with Quality!

Faster!Easier!Better!

No matter how stringent the automotive regulations, Allion can help you pass with ease.

Automotive cable testing requires not only exceptional instrument performance but also precise fixtures to ensure test accuracy. Allion boasts extensive experience in automotive cable testing and can rapidly provide testing services. Additionally, we offer problem analysis and corrective recommendations when issues arise, providing comprehensive testing services to help you easily navigate rigorous automotive standards.

Through our professional services, Allion assists clients in developing high-quality automotive cables, solving problems, and preventing issues that could lead to disqualification from automotive deliveries. Our services offer the following advantages:

Faster

Allion assists clients in quickly executing tests and resolving issues. When clients lack the necessary environment and capabilities, we leverage our advanced equipment and professional testing expertise to shorten their time by over six months, identify problems early, and provide solutions. We achieve this through the following advantages:

Comprehensive Equipment

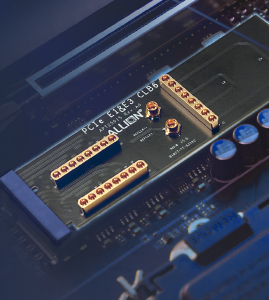

In automotive cable testing, unshielded twisted pair (UTP) cables are prone to external electromagnetic interference due to the lack of shielding, which can affect test accuracy. To address this issue, Allion has designed a Conductive Drum based on the OPEN Alliance TC-9 standards. The drum features an upright design, replacing the traditional flat setup. This not only saves space but also facilitates wire winding and quick installation.

Instruments are essential for testing, and not every device can easily meet the stringent automotive regulations. Allion is equipped with low noise floor network analyzers, which not only ensure compliance with standards but also help secure generous margin spaces for the test samples.

High-Frequency Testing Capability

Allion has extensive experience in measuring cable connectors, delivering accurate and rapid results to meet client measurement needs.

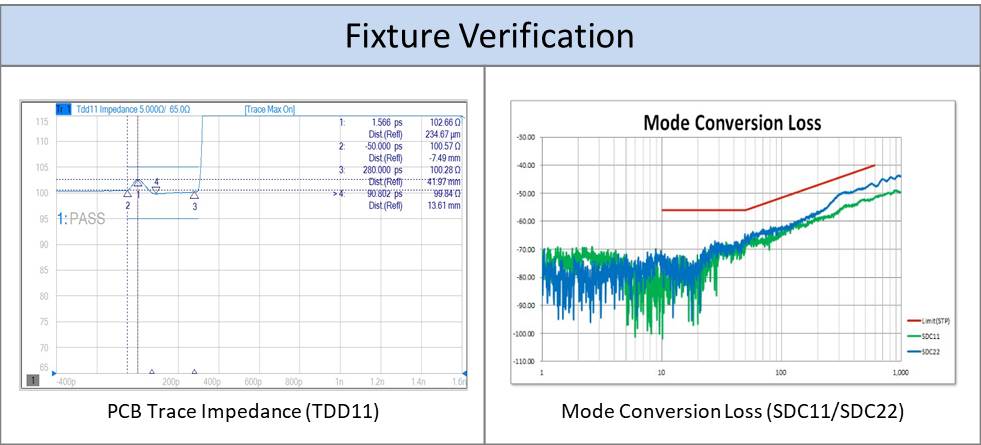

Easier

Automotive testing not only requires excellent instrument performance but also demands precise fixtures to ensure test accuracy. Fixture design must consider not only connector selection but also meet stringent specifications for PCB impedance and mode conversion loss.

Fixture Design Capability

Many clients looking to develop cable connectors lack the ability to design test fixtures. Allion has extensive experience in fixture design, creating high-quality fixtures that are stable and meet testing standards. This expertise helps you easily pass automotive regulations.

Better

Professional Consulting Services to Enhance Product Quality

Allion not only provides high-quality automotive cable testing services but also offers professional consulting services to help clients solve challenges in product development and production testing.

- Extensive Experience: Allion has rich experience in automotive cable testing and consulting, with a thorough understanding of various automotive testing standards and requirements.

- Expert Technology: Allion’s specialized cable technology team can offer professional consulting services.

If you are facing issues with automotive cables and need high-quality validation solutions, Allion can help you overcome challenges and achieve your product goals. Fill out the form and contact us today!