The Application Environment and Customer Needs for ECUs

In today’s technologically advanced automobiles, Electronic Control Units (ECUs) have become indispensable components. An ECU is a microprocessor-based control system that not only manages various functions within the vehicle but also acts as a central hub for receiving sensor data, processing information, and sending commands to actuators, effectively regulating the vehicle’s operations. Whether optimizing engine performance, enhancing safety features, or ensuring overall vehicle efficiency, ECUs play a crucial role.

ECUs are pivotal in modern vehicles, and rigorous testing is essential to ensure vehicle performance and safety. Therefore, ensuring consistency, effectiveness, standardization, and efficiency in ECU verification has become a key focus for many ECU suppliers.

Challenges and Issues Faced by ECU Manufacturers

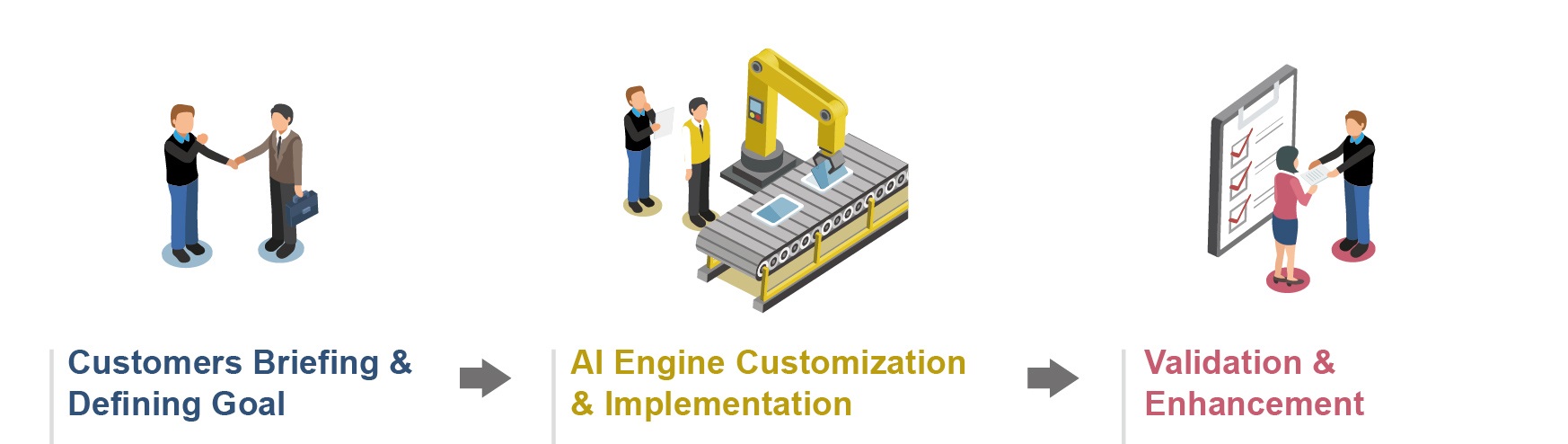

Traditional ECU manufacturers rely heavily on manual operations for production line testing, which naturally presents many areas needing improvement. For example, in the case discussed, the client needed to enhance the efficiency of ECU production line testing and required a consulting service provider with relevant expertise who could effectively communicate and understand their pain points. Ultimately, the client chose Allion, a company with long-standing experience in the automotive industry ecosystem and automotive testing field, hoping that Allion could help them build an effective ECU automation test management platform.

After understanding the needs, Allion immediately engaged in close communication and collaboration with the ECU supplier client. Through the discussion process, we identified that the client was primarily facing the following challenges:

Challenge 1: Limitations of Traditional Production Line Verification Methods

The client previously relied on fully manual testing and handwritten records for their production line verification methods. However, this approach has several limitations, including:

- Lack of Consistency in Test Results: Since test judgments are made through “manual interpretation,” there are often inconsistencies or human errors in the results.

- Lack of Traceability for Test Data: Handwritten records make it difficult to trace the origin and process of test data, impeding effective data analysis and quality traceability.

- Incomplete or Incorrect Test Data: Handwritten records may have omissions or errors, leading to incomplete data and affecting the accuracy of test results.

- Lack of Efficiency: Manual recording is time-consuming and labor-intensive, reducing testing efficiency and impacting production speed.

Challenge 2: Internal Challenges Due to Lack of Effective Processes and Expertise

- Lack of Effective Processes: Without established and effective testing processes and standards, test results are inconsistent, making it difficult to assess product quality effectively.

- Lack of Expertise: There is a shortage of specialized system platform developers, which hampers the ability to effectively construct and maintain automated testing systems.

Challenge 3: Gap in Expertise and Collaboration Capabilities

Choosing the right partner for building an automated test management platform is crucial. The client had also sought other system integrators, but due to the previous integrators’ lack of expertise in the testing field, the following issues arose:

- Inaccurate Understanding of Needs: The inability to accurately understand the client’s testing needs and processes led to system functionalities that did not meet actual requirements.

- Unreasonable Solution Design: The designed automated testing system did not meet the technical requirements for ECU testing, making it ineffective in completing testing tasks.

- Poor Communication: Ineffective communication and collaboration with the client led to project delays and failures.

Solution

To address the client’s urgent challenges and needs, Allion assisted in building an ECU automation test management platform. This platform integrates both hardware and software, fundamentally transforming and simplifying the testing and workflow processes based on a rational production line operation model. It not only enhanced testing efficiency but also improved product quality, thereby helping the client significantly upgrade their ECU production line testing operations.

The ECU Automation Test Solution Developed by Allion for the Client Includes:

Production Line Testing Process Management and Planning Services

- Optimization of Semi-Finished Product Automation Testing Processes

- Re-Optimization of Finished Product Automation Testing Processes

ECU Automation Test Management Platform Construction

- Automation Support for Production Line Testing

- Management and Analysis

- Product Quality Tracking

Benefits of Implementation: Key Features of the ECU Automation Test Management Platform

Faster – More Efficient and Accurate Testing: Production Line Testing Automation Support

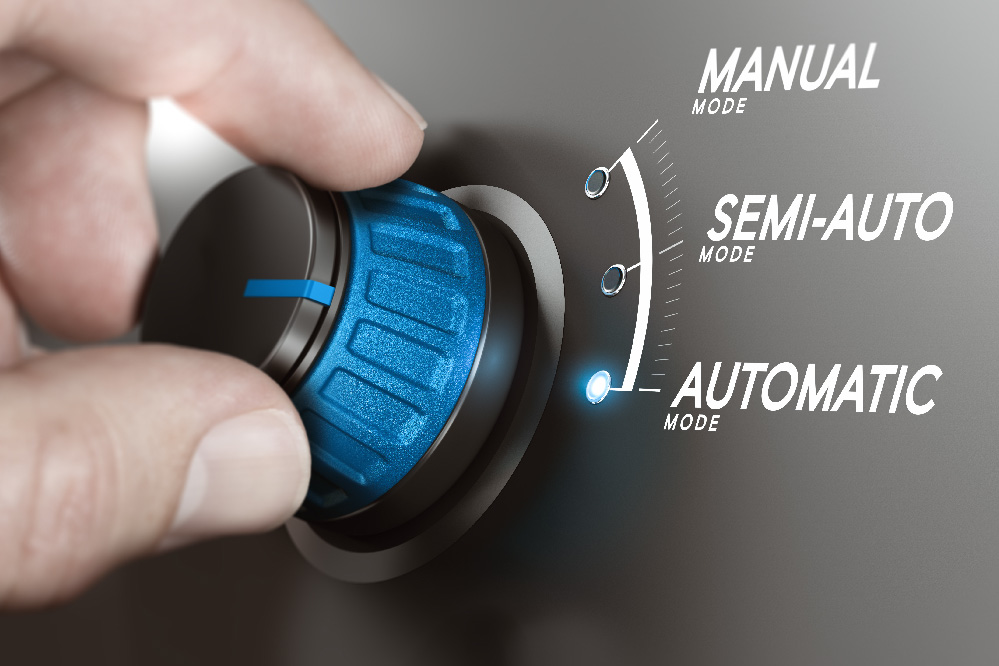

The ECU automation test management system transitions production line testing from manual to semi-automated processes. Users can easily leverage automation assistance to simplify the testing workflow, significantly increasing the testing speed on the production line by over 2 times. At the same time, it eliminates human errors, thereby enhancing the accuracy and reliability of testing.

- Automatic Identification of Sample Information with Barcode Scanners: Say goodbye to cumbersome manual record-keeping. Barcode scanners automatically input sample information, saving time and avoiding errors.

- Automatic Interpretation of Test Results: Test results are automatically determined by the system, eliminating the need for manual interpretation.

- Real-Time Display of Testing Process: Assists production line staff in monitoring progress and status in real-time.

- Automatic Generation of Test Reports: Test results are automatically generated into reports, significantly saving manual transcription time and avoiding transcription errors.

Easier – Simplified Management and Analysis: Comprehensive Control Over Product Quality

Administrators can gain more reliable visibility into product quality through the comprehensive product quality record retrieval functionality of the ECU automation test management system. The powerful management analysis features provide a complete view of all ECU test records and reports. By closely monitoring product quality trends, administrators can make informed decisions based on accurate and current data, quickly identify and address potential issues, and effortlessly ensure and control exceptional product quality.

Better – Enhanced Product Quality Traceability: Tracking Test History

The ECU automation test management platform offers detailed product traceability features to ensure testing excellence. Users can precisely control the history of test subjects. This functionality allows users to track each ECU’s test history and evaluate its performance at different testing stages. By analyzing the historical data of test subjects, users can identify patterns, optimize testing strategies, and continuously improve product quality.

Time to Market with Quality! Allion Builds the Path to Success for Your Products

In today’s rapidly changing manufacturing environment, the efficiency, accuracy, and reliability of testing are crucial, which has led to the demand for ECU automation test management platforms. As previously mentioned, the collaborating manufacturer had previously assessed and consulted with other system integrators for over a year without achieving their goals. Ultimately, Allion leveraged its extensive practical experience to help the client assess and complete the implementation in just two months, providing a comprehensive automation test solution that not only simplified the testing process but also offered multiple benefits, including improved product quality and reduced testing costs.

If you are looking for solutions to enhance production line testing management, feel free to contact us through the Inquiry form. The Allion consulting team will provide you with faster, easier, better one-stop integration consulting services, helping your product achieve its Time to Market with Quality goals!