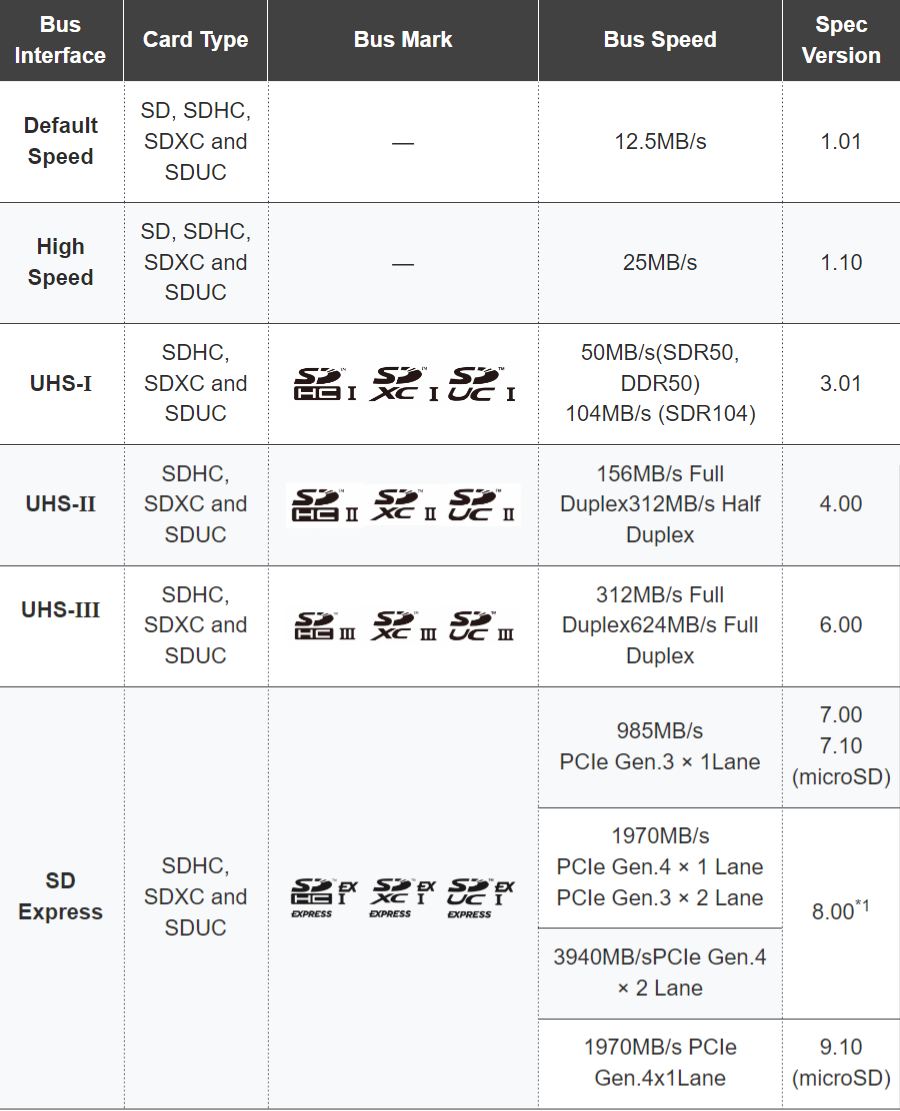

A camera is a magical tool capable of capturing beautiful moments, and those who have used cameras know that its mobile storage device lies within a tiny memory card, storing captured photos and videos. The most common storage card used is the SD card (Secure Digital Card). The development history of SD cards has been long, starting from speeds as low as 12.5MB/s in the past to the latest SD Express reaching up to 3940MB/s, supporting higher resolutions and larger capacities.

Potential Risks of Impedance Control in Card Readers

Every photo and video captured is a precious outcome, recording the beautiful moments in life. However, when it comes to transferring them via a card reader, encountering situations where reading or transferring becomes impossible can be a nightmare. Through in-depth investigation by Allion, it’s found that the potential cause could be poorly controlled impedance in the card reader, leading to decreased signal transmission quality and efficiency, or even errors or interruptions.

Impedance refers to the comprehensive performance of resistance and reactance in a circuit, which affects the flow of current and voltage changes, leading to potential causes of poor impedance control such as:

- Incorrect solder pad size: Improper design leads to insufficient component pads or improper solder connections. This can cause circuit discontinuity or instability, affecting the quality of signal transmission.

- Difficult processing: Depending on the capabilities of each board manufacturer, excessively small or precise designs may not be feasible for every manufacturer, increasing manufacturing costs and difficulty, and reducing product yield and reliability.

- Impedance control: Failure to consider matching impedance values may result in discontinuous impedance performance, leading to signal reflection and interference, affecting signal transmission efficiency and accuracy.

Actual Case

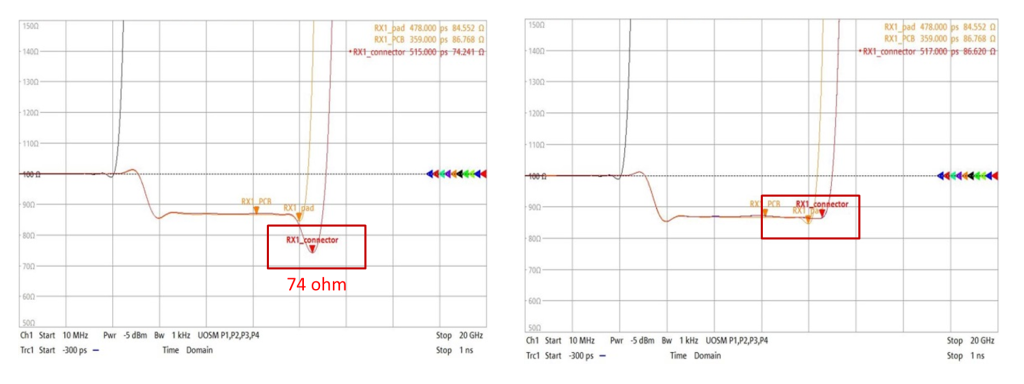

In a real case handled by Allion, a customer sent in an SD connector for testing, and the impedance measured at the red line RX connector was originally 74 ohms (left image), showing a significant impedance drop phenomenon. After our professional team’s advice and modifications, the impedance increased by around 12 ohms (right image), while maintaining impedance continuity.

Faster, Easier, Better! Memory Card and Connector Testing Consulting Services

Allion has abundant equipment resources and experience in solving various connector impedance control issues. With our professional consulting service team, you can enjoy a faster, easier, and better service experience, thereby enhancing market brand image and sales.

Faster:

Allion has decades of testing and debugging experience, and also participates in the development of various international association standards, enabling us to quickly and accurately identify various problems encountered by manufacturers and the key points of difficulty overcoming.

Easier:

Allion has rich testing equipment, analysis software, and fixture development capabilities, and regularly purchases representative products on the market as research samples. Therefore, we can assist customers in formulating customized testing content or fixtures that meet relevant product requirements, avoiding unnecessary detours and efficiently adjusting their products.

Better:

Allion has the most and best consulting experts in the industry, allowing you to easily enjoy the support of a strong and experienced team to help you effectively solve problems.

If you have any requirements or questions, please contact us.