Image Quality(IQ) Test Lab

Nearly all electronic devices, including notebook computers, smartphones, smart home appliances, and car recorders, are equipped with lenses. Considering today’s consumer demand, whether for camera imaging or image analysis, the common requirement is high-quality, high-resolution images. However, relying solely on the naked eye to subjectively judge image quality cannot fully ensure its true quality. Therefore, standardizing the quantitative analysis of image quality for related products has become even more important.

The Key to Enhancing Image Quality: “Image Quality Testing”

Image Quality (IQ) verification is primarily divided into two approaches: the first is objective analysis conducted in controlled environments and through datafication, and the second is evaluation based on subjective preferences after actual shooting. The following sections introduce the items and equipment used in the objective analysis approach.

Test environment

Darkroom: An environment where external light interference can be completely minimized. Typically, the background material is either a Neutral Gray (18% neutral gray) coating or an all-black, low-reflective material to create the optimal setting.

Test Equipment

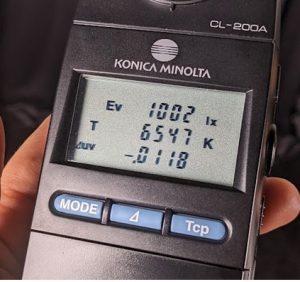

Chroma Meter: can accurately measure the brightness and color temperature of the ambient light source.

The number displayed on the top is the ambient light level, and the number on the bottom line represents the K value of the color temperature. For example, the number “1002” in the figure below means that the ambient light is 1002Lux, and “6547” represents the color temperature of 6547K, which is the common color temperature of the D65 light source.

Lamps

- Projector Lamps: These lamps need to evenly project the light source and reduce shadows, ensuring uniform illumination on the graph card. By controlling the color temperature and brightness, they help achieve test accuracy.

- Transmissive Lamps: These are used with transmissive charts, similar to slides, which require a transmissive light source to illuminate the chart for state measurement.

Cart

- MTF (resolution) graphic card: Standard test reflective graphic card using standard ISO12233, SFR, or ESFR

- Color test card: Commonly used 24-color standard test card

- Noise graphic card

- Dynamic range graphic card

Allion Image Quality Key Test Items for Your Products

Allion’s image quality consulting team has established a professional testing environment to verify the image quality of your products by measuring the following key items, ensuring optimal performance:

Clear Image

Resolution is a key indicator of image clarity, and the industry often uses the MTF (Modulation Transfer Function) as an objective evaluation standard. Generally, a higher MTF value indicates better image quality.

The test process can be broadly divided into the following steps:

- Select the light source to be tested.

- Use a standard test card to evaluate the MTF.

- Ensure stable and clear shooting.

Use the objective values provided by analysis software as a reference to evaluate the degree of clarity.

A high-quality image requires not only high resolution but also proper control of sharpness. Sharpening is one of the most critical criteria for evaluating image quality. If an image is very clear but the human eye perceives rough edges, it is often due to excessive sharpness. There is a positive correlation between sharpness and resolution, so managing sharpness while improving resolution is essential for maintaining image quality.

In addition to good resolution and sharpness, noise control is also crucial. An important metric for evaluating noise is the Spatial Noise level. This indicator measures the degree of unevenness in the image and assesses how noticeable the noise is.

Color Performance

The common standard for evaluating the color accuracy of a screen is ΔC. The test procedure involves fixing the light source on the object to be tested, using 24 color cards, and analyzing the color error through specialized software.

A common standard for evaluating color saturation on a screen is Color Saturation. It’s important to properly assess the saturation level, as over-saturation can lead to color distortion. The test procedure involves fixing the light source on the object to be tested, using 24 color cards, and analyzing the color saturation through specialized software.

White Balance is a critical criterion for evaluating an image’s color accuracy. It is automatically adjusted by the camera using a standard test color card, and the accuracy of the white balance is verified by analyzing the WBΔC through specialized software.

Exposure Accuracy measures how accurately an image is exposed. This is verified by shooting a standard test color card and analyzing the Y-channel through software to detect any over-exposure.

Texture and Detail

This test evaluates the retention of detail in an image. Texture fidelity is assessed by photographing CPIQ standard texture cards and analyzing the values using software to ensure that the texture remains accurate under different lighting conditions.

Dynamic Range

Dynamic range refers to the maximum brightness and exposure range that a camera can capture in an image. This metric is measured in dB. By photographing a standard test card designed to support dynamic range evaluation, the signal intensity at different brightness levels can be analyzed.

Gamma correction is used to verify the luminance and black-and-white response curves in an image. The OECF block on the eSFR card is utilized to analyze the brightness levels in different areas. This process ensures that the luminance across the screen is accurately represented, primarily through gamma correction.

Lens Control

Lens control is used to verify the lens’s ability to maintain image quality. Using standard test cards, the following key lens evaluation items can be analyzed:

- Lens Shading: This evaluates whether the lens produces excessive dark corners (vignetting). It is assessed by photographing the test card and analyzing the degree of shading around the edges of the frame.

- Field of View: This evaluates the lens’s field of view (FOV). The actual FOV is analyzed using the DOT test card.

- Lens Distortion: This evaluates the degree of lens distortion. The DOT test card is used to analyze and quantify the level of distortion.

Customized adjustments, visible quality

For products such as laptop built-in cameras, webcams, and car recorders, we conduct a series of image quality tests using a variety of lamps and standardized test cards. These comprehensive tests are tailored to the specific needs of our customers, ensuring the performance and effectiveness of these devices across different usage scenarios and meeting high user standards.

If you have any further needs for testing, verification, or consulting services related, please feel free to contact us through the online form.