Breaking Tradition – Applications and Challenges of High-Performance Rugged Laptops in Various Fields

Rugged laptops, also known as industrial-grade laptops, are specifically designed for use in harsh environments. Their applications are wide-ranging and include industrial manufacturing, public safety, healthcare, logistics and warehousing, energy and mining, as well as military and defense sectors.

Traditionally, these fields have prioritized product durability and security. However, with the trend towards high performance, there is a growing need for more powerful processors, graphics processors, and memory to meet advanced performance requirements. For industrial computer manufacturers who have historically focused on adopting mature technologies, this shift necessitates breaking away from traditional approaches and embracing new challenges in technology integration.

Not so simple! Challenges for Industrial Computer Manufacturers in Adopting Thunderbolt Technology

Recently, Allion collaborated with an industrial computer manufacturer that integrated Thunderbolt technology into their latest products to meet market demands for high performance. Thunderbolt is a high-speed data transfer technology with certain entry barriers. After the customer’s initial adoption of Thunderbolt technology, they encountered unexpected situations and unprecedented challenges.

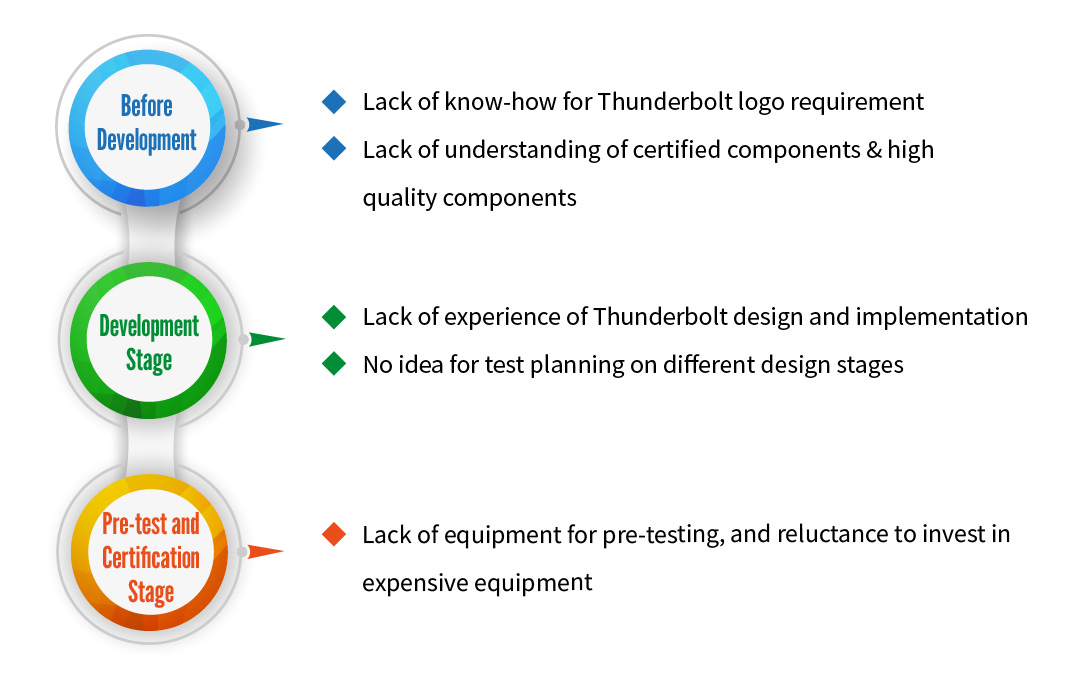

The actual encountered issues:

Analysis and planning, all-in-one! Allion’s comprehensive consulting service solutions

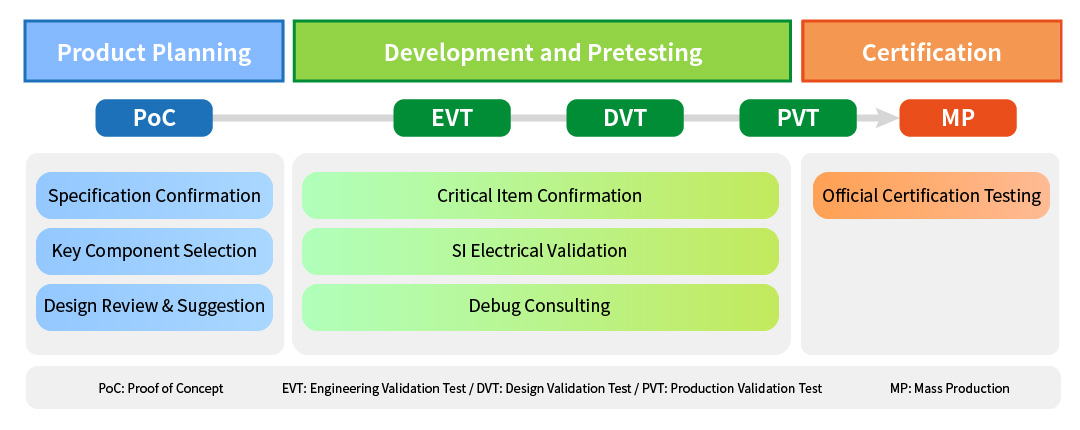

To address the challenges faced by this client, Allion leverages its extensive experience and capabilities to plan a series of consulting services as follows:

We have tailored various service offerings to address the client’s pain points at different stages. Specifically, during the Proof of Concept (PoC) phase, we have planned three key services.

Three Key Services

1. Specification Confirmation and Selection

Choosing the right platform is crucial as it can impact your system’s cost, power consumption, and performance. For instance, within the Intel ecosystem, different branches exist within the same generation of platforms to cater to various market demands, such as consumer platforms and high-performance platforms. Consumer platforms typically feature low power consumption and cost-effectiveness, suitable for general consumer products. On the other hand, high-performance platforms offer high power and performance capabilities, ideal for applications requiring intensive computation or demanding performance scenarios. Therefore, we assist clients in selecting the appropriate platform type based on specific application scenarios and requirements. This ensures that the system achieves the optimal balance among cost, power consumption, and performance.

2. Selection of Key Components

With years of extensive experience in Thunderbolt-related services, Allion identifies four key components that significantly impact Thunderbolt certification:

- PD Controller

- Re-timer

- Connector

- PCB

For instance, when considering a PD Controller, factors such as cost, serviceability, and integration play crucial roles. Some OEM/ODM manufacturers may prioritize cost when selecting a PD Controller supplier. However, solely cost-based decisions can sometimes lead to integration issues with Thunderbolt. Given that Thunderbolt is a high-speed data transfer technology, the choice of PD Controller is critical. If the selected PD Controller cannot integrate well, it may affect the overall product’s performance and stability.

Similarly, the choice of connector is vital, considering aspects like quality (insertion loss, signal integrity), cost, and type (Surface Mount Technology – SMT, Hybrid, Dual In-line Package – DIP). Connectors are also critical components of Thunderbolt products. Choosing an inappropriate connector type may lead to significant signal integrity issues, thereby impacting product reliability and performance.

Therefore, for these four key components, Allion not only assists clients in supplier verification but also provides recommendations for preferred manufacturers and part numbers. These recommendations are based on long-term cooperative relationships and ensure high performance from trusted suppliers.

3. Design Review

Design review is a critical step in ensuring product design quality and eventual success during the early stages of product development. It helps in identifying and resolving potential issues upfront, ensuring the correctness of the product design direction. Since this client is integrating Thunderbolt technology for the first time, Allion’s comprehensive design review primarily covers the following two areas:

● Circuit Review

■ Circuit Design & Revised

■ DRC Check

■ Unconnected Net Check

■ Components Search & Selection (Footprint and Datasheet)

● Layout Review

■ PCB Stack up (Layers Definition)

■ Layout Rule & Specific Notice

■ Layout Check & Review

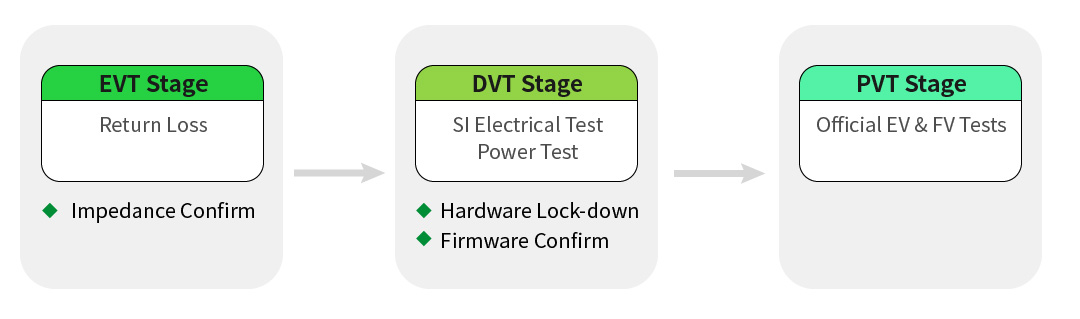

Verification Planning and Testing Phase

During the verification phase, we assist manufacturers in planning appropriate and necessary verification tests tailored to different design stages. This ensures that efficient and effective verification services are conducted at each stage while maintaining excellent quality standards.

Issue Analysis and Debugging Support

Throughout the project, Allion utilizes our extensive experience and equipment resources to assist clients effectively in resolving various design and verification issues. Our engineering team works closely with the client, providing comprehensive support in product design and verification planning. Our experts help identify and address design challenges, ensuring that the product meets all quality standards.

With Allion’s assistance, the client successfully launched their product to market on time and within budget. The product’s reliable quality has earned consistent praise from customers.

Time to Market with Quality!

Allion’s Professional Services and Capabilities

Allion is not just a certification laboratory accredited by major standards associations; we are also a company with comprehensive engineering consulting capabilities, providing extensive services in new standard implementation and design consulting. Our team of engineers at Allion has accumulated years of rich experience and professional knowledge to help you overcome design challenges and achieve your product goals.

- New Product Introduction (NPI) Training and Assistance: Allion’s expert team provides NPI training to help clients understand the process, requirements, and recommendations for new product development.

- Comprehensive Infrastructure Preparation: Allion assists clients in preparing the necessary infrastructure for product development, including testing equipment and a highly experienced research and development (R&D) and verification team.

- Capability Consulting: Allion offers capability consulting to help clients enhance their design and production capabilities.

- Selection of Key Components: Allion assists clients in selecting key components that meet product requirements and ensure supply chain stability.

- Design Review Services: Allion’s R&D team provides design review services to help clients identify and resolve potential issues early, ensuring correct product design direction.

- Verification Planning Services: Allion plans meaningful and reasonable verification projects according to the design development cycle, swiftly assisting clients in achieving standard certifications.

Accelerate Your New Product Launch Schedule Faster! Easier! Better!

Allion’s Design Consulting Services Assist You:

- Shorten Time to Market: Based on our extensive experience, for a manufacturer like the one in this case study, which had never previously implemented Thunderbolt, initial implementation typically takes considerably longer—often more than three additional months compared to this case.

- Comprehensive Planning Proposals: Making the adoption of new designs no longer a daunting task.

- Reduce Product Development Costs: Longer development times translate to higher design and development costs. Saving three months can save at least millions of New Taiwan Dollars in costs.

- Quality and Risk Management: Enhance product quality while concurrently reducing product risks.

If you are introducing new technology, Allion can assist you in overcoming challenges and achieving your product goals. Contact us now to learn more.