The Evolution and Challenges of PCIe Technology

PCIe (Peripheral Component Interconnect Express) technology is a critical interconnection technology in today’s computer systems, with high-frequency and high-speed characteristics that impose stringent requirements on system performance and reliability. With the introduction of new generation standards such as PCIe 5.0, 6.0, and 7.0, data transmission rates continue to rise, presenting even tougher challenges for electrical signal integrity and stability.

• High Frequency and Speed: Higher data transmission rates mean higher signal frequencies, which increases the demands on signal integrity and timing. The data transmission rates for PCIe 5.0 and PCIe 6.0 are 32 Gbps and 64 Gbps per lane, respectively, while PCIe 7.0 reaches up to 128 Gbps per lane.

• Diverse Applications: PCIe is not only used in traditional computer systems but has also expanded into consumer electronics, automotive, industrial, and other fields, each with varying reliability and stability requirements.

• Signal Complexity: High-speed transmission, various signal types, and complex encoding methods make the measurement of PCIe signals increasingly complicated.

Reasons for Essential PCIe Electrical Signal Measurement

• Ensuring Signal Integrity: PCIe signals are susceptible to noise and crosstalk during high-speed transmission, which can lead to decreased signal integrity and even errors.

• Early Detection of Potential Issues: Precise measurements can help identify and resolve potential problems, preventing failures or performance issues in actual applications.

The Importance of PCIe Testing Fixtures

To address the challenges posed by the development of PCIe technology, PCIe testing fixtures play a vital role. As tools to assist in the testing of PCIe products, they provide accurate and reliable measurement environments, ensuring the accuracy of test results.

• Providing a Standardized Testing Environment: Testing fixtures are designed according to PCIe standards, offering a compliant testing environment that ensures comparability of test results.

• Improving Testing Accuracy: Testing fixtures, paired with high-precision measurement instruments, can accurately capture PCIe signals, enhancing testing precision.

PCIe testing fixtures and electrical signal measurement are critical for ensuring the performance and reliability of PCIe systems. Through precise measurements, potential issues can be detected and resolved early, improving product quality and reliability.

Customer Challenges and Issues

Analyzing Customer Pain Points—Diverse PCIe Form Factor Testing Difficulties

The customer is a technology giant spanning the consumer PC and server sectors. To ensure superior performance and reliability of their products, they plan to establish a high-frequency PCIe testing environment internally. However, with the rapid development of PCIe technology and the diversification of the customer’s product line, they have encountered unprecedented challenges in testing after introducing the PCIe 5.0 specification.

Identifying the Problems:

- Form Factor Limitations: The current CEM standard test fixtures for PCIe 5.0 from the PCIe Consortium do not meet the customer’s diverse PCIe form factor requirements, such as M.2, U.2/U.3, EDSFF E1/E3, and OCP NIC 3.0. The lack of dedicated test fixtures for these form factors has hindered testing efforts.

- Testing Delays Due to In-House Fixture Development: Due to the lack of suitable testing fixtures, the customer has had to consider developing their own, which consumes significant time and manpower, severely affecting the product launch timeline.

- Inaccurate Testing Data: In-house developed fixtures may lead to inaccurate test data, failing to accurately reflect product performance and increasing risks after market launch.

- Increased Costs: Developing their own fixtures not only consumes R&D resources but also adds to overall costs.

Specific Needs Analysis:

The customer urgently requires a PCIe testing solution that can meet the following demands:

- Comprehensive Form Factor Support: The solution must cover various PCIe form factors, including M.2, U.2/U.3, EDSFF E1/E3, and OCP NIC 3.0, providing a one-stop testing fixture solution.

- Ensuring Product Quality: Appropriate test fixtures are needed to accurately measure the signal quality of products across different form factors, ensuring the accuracy of test data and maintaining market competitiveness.

- Cost Reduction: Avoid the costs associated with developing their own fixtures to lighten the financial burden.

Consequences of Not Effectively Addressing These Issues:

If the above challenges are not effectively resolved, the customer will face the following risks:

- Product Launch Delays: Inaccurate measurements will directly impact the product launch timeline, leading to decreased market competitiveness.

- Product Quality Issues: Inaccurate test data could result in performance or reliability issues in the market, damaging brand reputation.

- Increased Development Costs: Developing their own fixtures will raise R&D costs.

If these issues are not effectively addressed, the customer will encounter risks such as delayed testing progress, unguaranteed product quality, and decreased market competitiveness. Therefore, the urgent need for PCIe test fixtures that support multiple form factors is their greatest challenge.

Allion PCIe Test Fixture Solutions: Addressing Various Customer Challenges

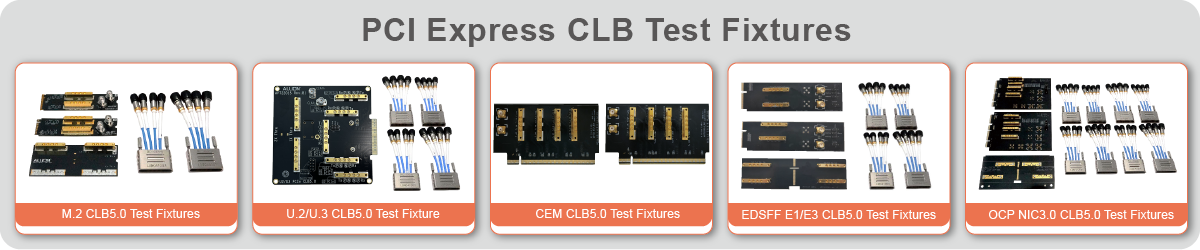

– Comprehensive Form Factor Support: Tailored Solutions for Customers

In response to the challenges faced by customers in PCIe testing, Allion is the first company in the world to launch test fixtures that cover all PCIe form factors. We provide PCIe test fixture solutions for various form factors, including M.2, U.2/U.3, EDSFF E1/E3, and OCP NIC 3.0, aimed at meeting customers’ comprehensive testing needs. These fixtures are meticulously designed for immediate use, eliminating the need for customers to develop their own solutions and ensuring that testing processes are not hindered by equipment limitations. By implementing our fixtures, customers have successfully overcome the testing challenges they faced.

Allion’s Exclusive Test Fixtures: A Guarantee of Quality and Reliability

High-Quality Service That Creates Value for You. Time to Market with Quality!

Faster, Easier, Better!

With Allion’s years of deep industry experience, our exclusively developed PCIe test fixture solutions offer three core advantages to customers:

Faster:Accelerating Testing Processes and Reducing Time to Market

- Comprehensive Form Factor Coverage:

- Full support for various form factors including M.2, U.2/U.3, EDSFF E1/E3, and OCP NIC 3.0, meeting diverse design validation needs.

- Immediate Sales and Delivery:

- Rigorously validated test fixtures are ready for immediate use, eliminating the need for development time.

- Improved Testing Efficiency:

- With Allion’s dedicated test fixtures, customers can not only enhance testing efficiency but also ensure accurate testing across all PCIe interfaces.

- Shortened Product Launch Time:

- Avoid delays caused by developing your own test fixtures, allowing for a swift initiation of testing processes.

Easier:Optimizing Testing and Reducing Costs

- Reduced Development and Deployment Costs:

- Customers do not need to allocate resources for self-developed test fixtures, significantly lowering development and deployment costs. We provide ready-made fixtures that immediately address testing needs, avoiding high costs and technical risks associated with self-development.

- Lower Technical Barriers:

- Allion’s PCIe fixtures are expertly designed using dual-line calibration technology, allowing customers to complete calibration without the need to purchase both Compliance Load Board (CLB) and Compliance Base Board (CBB) fixtures simultaneously.

- Comprehensive Technical Support:

- Our professional team provides thorough technical support and services to address all your inquiries.

Better:Industry-Recognized Fixtures that Enhance Testing Quality

- High-Precision Design:

- Fixtures are precisely designed to reinforce the SMPM connector structure and feature flexible cable accessories that support up to 40GHz, ensuring the accuracy and consistency of test data.

- Industry-Leading Recognition:

- Our fixtures are utilized by major brands, manufacturers, and chip suppliers for their internal testing, demonstrating the reliability and professionalism of our solutions.

- Comprehensive PCIe Testing Support:

- Meeting the specialized testing needs for various PCIe form factors without any gaps.

- Allion has also developed CLB fixtures for calibrating and measuring host/systems, as well as CBB fixtures specifically for calibrating and measuring Add-in Cards (AIC), providing comprehensive support for various product testing needs.

Choose Allion and Win from the Start!

- Immediately address testing needs without delay.

- Significantly reduce development and deployment costs.

- Enhance testing efficiency and ensure reliable results.

- Minimize testing risks and strengthen product competitiveness.

Allion’s PCIe test fixture solutions help you complete PCIe testing faster, easier, and more effectively, allowing you to seize market opportunities!

In addition to PCIe test fixture solutions, we also offer PCIe automation testing solutions. If you’re interested in our PCIe automation testing solutions, feel free to contact Allion at any time.

Read more |

Read more about Allion Test Fixtures

About Allion PCIe Multiport System (APMS)