SD memory cards are a compact storage medium for personal data and multimedia files (audio, images, and video). SD cards feature large storage capacity and fast data transmission speeds in a small form factor for use in a wide range of products. Driven by the trend for slimmer and lighter consumer electronics, the market for SD cards is growing fast. Typical applications include digital cameras, mobile phones, multimedia players, printers, computer systems, card readers, home entertainment equipment, and in-vehicle infotainment systems.

Thorough Testing Ensures SD Card Quality

SD Card Quality Validation Hierarchy (QVH)

The SD Card Quality Validation Hierarchy (shown above) includes four test types:

- Compliance – product certification testing based on industry standard specifications for hardware design, signal quality, and other protocols

- Performance – competitive analysis of product features and comparison of measured SD read/write speeds versus marketing statements

- Reliability – stress test SD products by simulating extended usage or exposure to hostile environmental conditions to evaluate product durability and stability

- Interoperability – test product interoperability with other branded hardware and software in the target ecosystem (e.g. IVI, IoT, OTT, …)

Most manufacturers invest in Compliance testing, which is why it is at the bottom of the SD Card Quality Validation Hierarchy (QVH). At this level of the hierarchy, companies have the freedom to self-test or outsource testing to an independent test laboratory. For either case, SD Association offers a Conformance Test Tool (CTT) for product compliance testing based on their published standards and specifications.

As products move up the value chain, quality becomes an increasingly important factor. To compete with other brands, leading manufacturers must go beyond basic Compliance testing and invest in Performanceand Reliability testing. But as the scope and volume of product testing increases, so do the associated costs of test equipment purchase, training, calibration, and maintenance. At this point, many companies seek to reduce costs by turning to a professional testing laboratory.

Since Compliance testing represents the minimum standard of product quality, it occupies the lowest level of the SD Card QVH, followed by Performance and Reliability testing in the middle levels, andInteroperability testing at the top. Product quality optimization can only be achieved through systematic and comprehensive compatibility testing of SD memory cards and SD Host devices. Since most SD cards are meant to function in combination with a broad range of SD Host devices, often from competing brands,Interoperability represents the gold standard in SD Card Quality Validation.

As we have said, most companies perform basic Compliance testing, but not every company follows a total quality management approach. As a result, many products fail at the initial design or production stages, passing superficial quality inspections while hiding serious design or manufacturing flaws. As we have discussed, these types of problems can be avoided by implementing all four levels of the SD Card Quality Validation Hierarchy.

SD Host Ecosystem

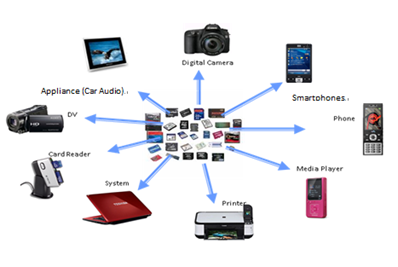

The SD standard, with its reliable interoperability and easy-to-use format, has become the number one portable storage solution for consumers, with over ninety percent (90%) market share, according to recent figures. In addition, SD cards are compatible with most camera brands, including Canon, Nikon, Kodak, Panasonic, and Konica Minolta. As shown in the graphic below, this popularity extends to many other product categories, including mobile phones, media players, printers, PC systems, digital video recorders, and automotive appliances.

SD Host Ecosystem

SD Host Interoperability Requirements

As mentioned previously, Interoperability testing ensures that SD cards can function well with a broad range of SD Host products, as summarized in the points below:

- SD cards must be compatible with high capacity SD hosts (SDXC/SDHC/SD)

- SD cards must be compatible with various SD specifications (SD2.0/3.0/4.0)

- SD cards might be used in unexpected ways (e.g. microSD with adaptor)

- Content generated by one SD host might be consumed on another

To ensure that SD cards behave correctly with all types of SD Host devices, it is vital to perform comprehensive interoperability testing. In reality, Interoperability is no less important than Compliancetesting, since incompatible SD cards are effectively useless for end users. Since there are still many interoperability issues between SD cards and host devices, SD members should work together to overcome and troubleshoot these problems cooperatively and systematically.

SD Host Interoperability Issues

SD Host interoperability is an issue of concern for both SD card and SD host vendors. Since Allion has access to thousands of test devices, we prepared this summary report for the benefit of the SD member community (and other interested parties).

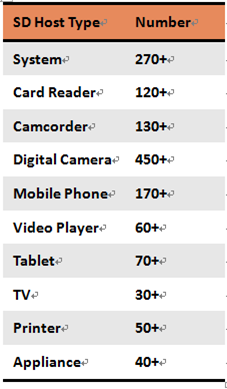

For this report, we tested over one thousand SD Host devices. The table below shows the number of SD Host devices in each of ten categories. The Digital Camera and System categories represented about half of the total devices tested (1,390+).

Interoperability Issue Summary

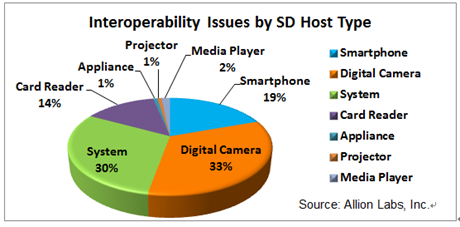

In total, 120 interoperability issues were identified. We found that the Digital Camera and System categories had the most interoperability issues, following by the Smartphone and Card Reader categories.

After some analysis, we found that most interoperability issues occur in four common test scenarios:

(1) Plug/Unplug Enumeration

(2) User Behavior (Format, I/O Errors)

(3) Power Management (Cold/Warm Boot, Sleep)

(4) Performance Evaluation

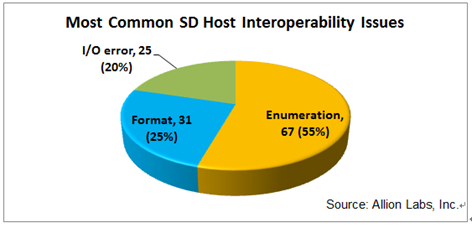

The figure below shows the most common SD Host interoperability issues.

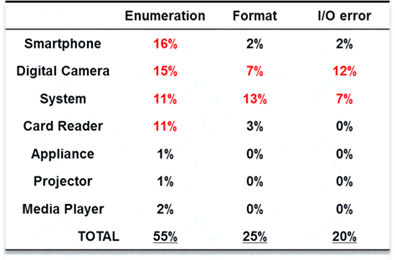

This figure shows that the most common interoperability issue was plug/unplug Enumeration. Since we came across this issue on almost every SD host device that we tested, it is also the most common issue across device categories. This issue is very serious because once it occurs, the whole device becomes impossible to use. Mobile Phone (16%), Digital Camera (15%), System (11%) and Card Reader (11%)categories are the most likely to experience this issue.

The next most common issue related to the SD card Format (25%) operation. We found that devices in theSystem (13%) category were much more likely to have formatting issues than those in the Digital Camera (7%) category. Roughly, 20% of SD host devices encountered an I/O error, with fewer in the System (7%)category and many more in the Digital Camera (12%) category.

Source: Allion Labs, Inc.

Discussion

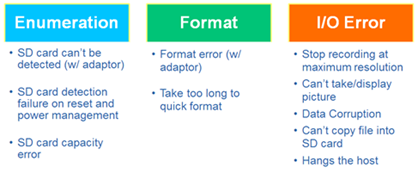

We are concerned that interoperability issues occurred in SD cards and devices from many different vendors. We have summarized the most common errors in the table below. These errors have multiple causes, including electrical signal quality, impedance matching resistance, firmware defects, and so forth.

How can manufacturers reduce interoperability issues? They can start by establishing more effective and comprehensive test protocols that include all four levels of the SD Card Quality Validation Hierarchy (QVH). Improving product interoperability makes sense for individual product vendors because they can gain access to high-value markets and increase overall margins. It also makes sense for the SD industry at large because improved interoperability will improve the end user experience, so that this technology can maintain its position as the dominant portable storage solution.

With this report, Allion hopes to move forward the discussion related to SDA interoperability. As an accredited ISO/IEC 17025 test laboratory and SD Association (SDA) test laboratory, we have many years of SD product test experience behind us.

For more information about our SD validation and compliance services, please visithttp://www.allion.com.tw/SD.html or contact us directly at service@allion.com.